Program Background:

As a widely used tool in industrial production and daily life, the quality and precision of blades directly affect the quality and productivity of products. Various defects may exist on the surface of blades, such as scratches, cracks, wear, etc. These defects not only affect the service life of blades, but also may adversely affect the production process and product quality. Therefore, efficient and accurate inspection of blades is particularly important.

Traditional blade inspection methods rely on manual visual inspection or the use of contact measuring tools, these methods are not only inefficient, but also susceptible to the influence of human factors, resulting in the lack of accuracy and reliability of the test results. With the continuous development of laser technology and machine vision technology, laser autofocus microscope system has gradually become an ideal choice for blade inspection.

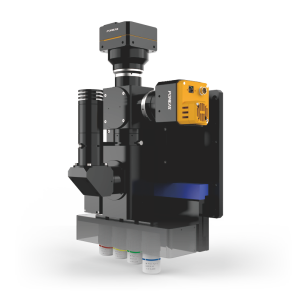

During the inspection process, a laser beam passes through an illuminated pinhole to form a point light source that scans the surface of the object under test (e.g., a blade). The illuminated point is imaged at the detection pinhole, received point by point or line by line by a light point multiplier tube or a cold electrocoupler device behind the detection pinhole, and quickly formed into an image on a computer monitor screen. The realization of autofocus relies on the precise control of the relationship between the object distance and the focal length. Through the image processing algorithm, the spot pattern is converted into the out-of-focus amount of the objective lens, and according to the out-of-focus amount, a pulse signal is sent to control the motor movement, thus realizing the autofocus of the microscope system.

Focus to the advantage of the blade:

1. High-precision Inspection: The laser autofocus microscope system is capable of realizing micron-level inspection accuracy, clearly identifying tiny defects on the blade surface, such as scratches, cracks, etc., ensuring the accuracy and reliability of the inspection results.

2. Non-contact inspection: The laser autofocus microscope system adopts a non-contact inspection method, which avoids the damage and contamination that may be caused to the blade surface by the traditional contact measuring tools, and protects the original state of the blade.

3. Rapid Inspection: The system has a fast autofocus function, which is able to complete the inspection task of a large number of blades in a short time, improving the inspection efficiency.

4. Intuitive display: The inspection results are displayed in the form of intuitive images or videos, which is convenient for researchers and production personnel to analyze and judge, and reduces the influence of human factors.

5. Wide range of applications: The laser autofocus microscope system is not only suitable for blade inspection, but can also be applied to other fields that require high-precision, non-contact inspection, such as semiconductor inspection, material science, and so on.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com