The accuracy of gears, a core component in mechanical transmissions, is directly related to the performance and lifetime of the entire mechanical system. However, the measurement of gears often faces a series of challenges, including complex geometries, high accuracy requirements, and variable measurement environments.

Measurement Difficulties:

1、Complex geometry: Gears usually have complex tooth shapes and helical structures, which brings challenges to traditional measurement methods.

2、High precision requirements: the dimensional accuracy and shape accuracy of gears are critical to the smoothness and efficiency of mechanical transmission, so high precision measurement equipment is required.

3、Variable measurement environment: Temperature, humidity and vibration in the industrial environment may affect the accuracy of the measurement results.

4、Efficiency and cost: Traditional gear measurement methods are time-consuming and costly, which is especially true in mass production.

Solution:

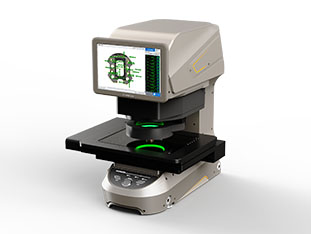

The POMEAS Flash Tester is a high precision measuring device designed to address the difficulties of gear measurement, and it solves these problems through the following features:

1、High-precision Imaging Technology: The high precision imaging technology used in the POMEAS flash tester is able to clearly capture every detail of the gears, ensuring the accuracy of the measurement results.

2、Advanced Optical System: Equipped with advanced optical system, including high-resolution lens and stable light source, it can maintain measurement stability even in complex industrial environments.

3、Automated Measurement Process: The POMEAS flash tester supports automated measurement process, which reduces manual operation, improves measurement efficiency and lowers costs.

4、Powerful Data Processing Capability: Built-in powerful data processing software enables rapid analysis of measurement data and generation of detailed reports for subsequent design and manufacturing improvements.

5、Multi-Dimensional Measurement: The POMEAS Flash Meter is capable of 2D and 3D multi-dimensional measurements to comprehensively assess the size, shape and positional accuracy of gears.

6、Environmental Adaptability: Designed with the diversity of industrial environments in mind, the POMEAS Flash Meter has excellent environmental adaptability and is capable of stable operation under a wide range of conditions.

7、User-friendly interface: Provides an intuitive user interface that simplifies the measurement setup and data analysis process, making it easy to use even for non-professionals.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION