As an important sealing element, gaskets are widely used in various fields of daily life and industrial production. They are designed to fill the gap between two or more connected parts to prevent the leakage of gases, liquids or solid particles, ensuring the normal operation and safety of equipment. From sealing door strips of household appliances (e.g. refrigerators, washing machines), to oil seals and water pipe joints of automobile engines, to sealing of industrial pipelines, valves and pumps, gaskets play an indispensable role.

Since the sealing effect of a gasket is directly affected by its dimensional accuracy, the measurement requirements for its dimensions are extremely strict. Any small dimensional deviation may lead to poor sealing and consequently to leakage problems. The requirements are as follows:

- Precision requirements: Micron-level or even higher measurement accuracy is required to ensure a perfect fit between the gasket and the mating parts.

- Non-contact measurement: To avoid damage or deformation to the gasket, non-contact measurement is preferred.

- Fast and efficient: In a mass production environment, gasket dimensions need to be measured quickly and in batches to improve production efficiency.

- Automation and Intelligence: Combining modern image processing technology and automation control technology to realise the automation and intelligence of the measurement process and reduce human error.

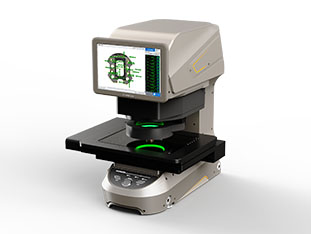

The POMEAS Image Gauge, as an advanced non-contact measuring device, demonstrates significant advantages in the measurement of gasket dimensions:

1. High-precision Measurement: Adopting high-precision image sensor and advanced image processing algorithm, it is able to achieve micron or even nano-scale measurement accuracy, which meets the strict requirements of gaskets on dimensional accuracy.

2. One-button operation: Users only need to set the measurement parameters, and the measurement process can be completed automatically with one-button startup, which greatly simplifies the operation process and reduces the requirement of operator's skills.

3. Fast Measurement: With high speed image acquisition and processing capability, POMEAS image measuring instrument is able to complete the measurement of a large number of gasket dimensions in a very short period of time. As mentioned in the article, 300 product dimensions can be measured in 3 seconds with one key, which greatly improves the measurement efficiency.

4. Non-contact measurement: Non-contact measurement is adopted, avoiding the problem of gasket damage or deformation that may be caused by traditional contact measurement, ensuring the accuracy and reliability of measurement.

5. Intelligent analysis: Built-in intelligent analysis software automatically identifies and calculates key dimensional parameters of the gasket, such as diameter, thickness, width, etc., and generates detailed measurement reports for subsequent data analysis and quality control.

6. Flexibility and Adaptability: POMEAS Image Gauge supports the measurement of gaskets of various sizes and shapes, which can be easily adapted to different products by changing fixtures or adjusting the measurement procedure.

The ability to measure gasket dimensions quickly and accurately makes the POMEAS Image Gauge the ideal choice for gasket sizing by major manufacturers.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com