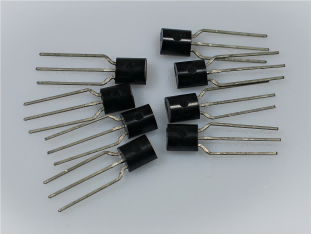

In the electronics manufacturing industry, the quality of ICs (integrated circuits) is directly related to the performance and reliability of electronic products.The width, spacing and number of IC pins are key indicators for assessing IC quality. Traditional inspection methods often rely on manual inspection, which is inefficient and prone to errors. With the development of automation technology, the use of telecentric lenses for IC pin inspection has become an effective means to improve inspection efficiency and accuracy.

Testing Requirements:

- Accurate Measurement: Accurately measure the width and spacing of IC pins.

- Quantity Identification: Accurately identify the number of IC pins.

- High Repeatability: Inspection results need to be highly repeatable to ensure consistency.

- Adaptability: Able to adapt to different types and sizes of IC inspection needs.

Detection Program:

POMEAS high-resolution telecentric lens:

① Telecentric Characteristics: Telecentric lenses provide distortion-free images to ensure accurate measurements.

② High Resolution: High resolution ensures that details of IC pins are clearly captured even at high magnification.

③ Depth of Field: Large depth of field allows image clarity to be maintained at different working distances.

High Definition Industrial Camera

① Image quality: HD industrial cameras provide high quality images, providing a good basis for subsequent image processing and analysis.

② Speed and Stability: Fast image acquisition speed and high stability ensure the continuous operation of the production line.

Plane illuminant

① Uniform Illumination: The flat light source provides uniform illumination to avoid image distortion caused by uneven lighting.

② High Brightness: Sufficient brightness ensures clear imaging even in low-light environments.

Implementation Steps:

① System construction: Installation of high resolution telecentric lens, high definition industrial camera and flat light source from POMEAS to ensure the accurate docking of equipment and inspection stations.

② Light Source Adjustment: Adjust the brightness and angle of the plane light source according to the material and reflection characteristics of the IC pins to realize the best lighting effect.

③ Image Acquisition: Activate the industrial camera to acquire high-definition images of IC pins to ensure that all details are clearly captured.

④ Image processing: Use image processing technology to analyze the captured image, measure the width and spacing of IC pins, and identify the number of pins.

⑤ Data analysis: through algorithm analysis, automatically calculate the size and number of IC pins to ensure the accuracy of the measurement results.

⑥ Quality judgment: Based on the measurement results, automatically determine whether the IC meets the quality standards.

⑦ Feedback control: Feedback the inspection results to the production line control system to reject or mark the unqualified ICs.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com