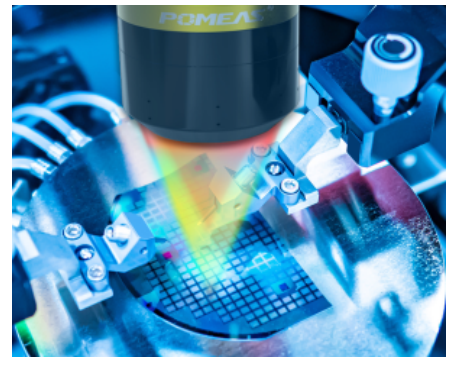

In the field of semiconductor wafer fabrication, high-precision and high-efficiency measurement and inspection technology is the key to ensure product quality and productivity. Spectral confocal sensors, as an advanced non-contact measurement tool, have been widely used in the semiconductor wafer industry due to their high accuracy, high stability and wide applicability.

Overview of spectral confocal sensors:

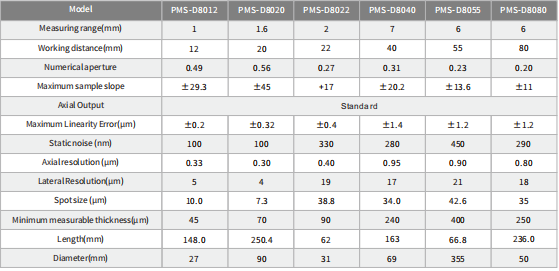

POMEAS SFS-8080 Spectral Confocal Sensor is an advanced measurement device that combines high accuracy and stability. The sensor adopts the spectral confocal technology to analyze the spectral characteristics of substances at different wavelengths and realize the accurate measurement of the surface topography, height, thickness and other parameters of the object.SFS-8080 not only has a very high measurement accuracy (up to the sub-micron level), but also has a wide range of measurements and a good environmental adaptability, and is able to work under the high temperature, high pressure and other harsh conditions.

Practical applications:

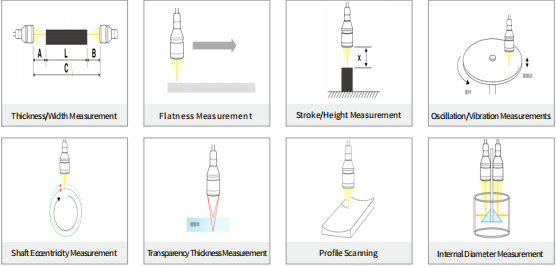

1. Wafer size and surface topography measurement:

In the semiconductor wafer manufacturing process, the dimensional accuracy and surface topography of wafers have a direct impact on the chip performance. POMEAS SFS8080 spectral confocal sensor is capable of non-contact measurement of the dimensional deviation of wafers, surface roughness and flatness and other key parameters. Its high-precision measurement capability ensures that the wafer size deviation is less than 0.002 mm/m, and the deviation between surface roughness and wafer centerline is less than 0.01~0.02 um, thus meeting the high-precision requirements of wafer manufacturing.

2. Wafer thickness uniformity detection:

The uniformity of wafer thickness is crucial to chip performance, POMEAS SFS8080 spectral confocal sensor can accurately measure wafers at different positions and depths to ensure the consistency of wafer thickness. Through real-time feedback of the measurement data, production personnel can adjust the process parameters in time to ensure the uniformity of wafer thickness, thus improving the performance and reliability of the chip.

3. Wafer surface defect detection:

Tiny defects on the wafer surface such as scratches, cracks, etc. will affect the performance and reliability of the chip. POMEAS SFS8080 spectral confocal sensor can generate high-resolution three-dimensional image, and through the spectral analysis technology to identify the wafer surface of the small defects. This non-destructive inspection method not only improves the inspection efficiency, but also avoids the damage and contamination that may be caused by traditional contact measurement.

4. Quality control after wafer polishing:

Wafer polishing is one of the important parts of the semiconductor manufacturing process. The quality of the polished wafer surface directly affects the smoothness of the subsequent process steps and the final performance of the chip.POMEAS SFS8080 spectral confocal sensor can monitor the thickness and flatness of the polished wafer surface in real time, to ensure that the quality of the polishing process requirements. At the same time, its non-contact measurement method avoids secondary contamination and damage that may be caused by traditional contact measurement.

5. Wafer Bump 3D topography measurement:

In advanced packaging processes, the 3D morphology of bumps on wafers is critical to package quality. The SFS8080 Spectral Confocal Sensor from POMEAS is able to accurately measure the height, diameter, and coplanarity of the Bump, providing accurate data to support the packaging process. With the real-time feedback of the measurement data, the production staff can adjust the packaging process parameters in time to ensure that the quality of the package meets the design requirements.

The high precision, high stability and wide applicability of POMEAS SFS-8080 spectral confocal sensor make it an indispensable and important tool in wafer fabrication, inspection and quality control. It will play a more important role in the semiconductor wafer industry and provide strong support for the development of semiconductor industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com