Spectral Confocal Sensor Principle:

Spectral confocal sensor is a high-end sensor combining spectral analysis and confocal measurement technology, which not only measures the spectral properties of substances at different wavelengths (such as absorption, emission, scattering, etc.), but also precisely controls the measurement focal point through the principle of confocal, realizing non-contact and high-precision three-dimensional measurement. By analyzing the specific response of matter to light, this sensor can quickly and accurately obtain the surface topography, thickness, position and other key parameters of the measured object, providing strong technical support for industrial automation, quality control and other fields.

Selection Tips:

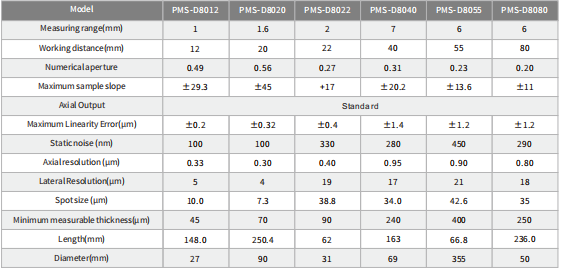

1、Measurement wavelength range: Different models of spectral confocal sensors may support different wavelength ranges, you need to choose the appropriate wavelength range according to the spectral characteristics of the object to be measured.

2、Working distance: The optimal measurement distance between the sensor and the object to be measured varies from model to model, and needs to be selected according to the space constraints and measurement requirements in the actual application scenario.

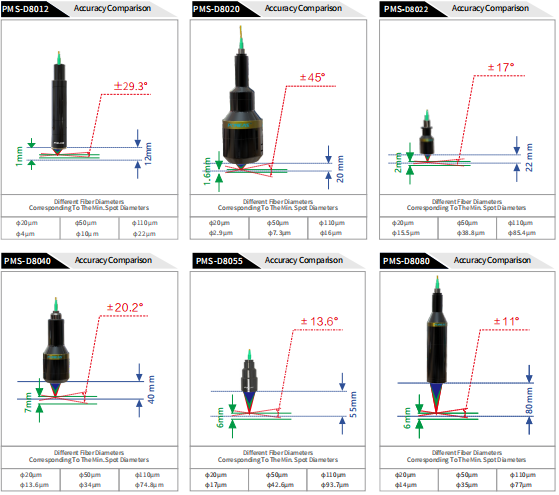

3、Numerical Aperture (NA): The numerical aperture determines the measurement accuracy and depth resolution of the sensor, a larger numerical aperture usually means higher measurement accuracy and shorter measurement depth.

4、Work application: According to the specific application field (e.g. metal processing, electronic manufacturing, glass inspection, etc.) and measurement requirements (e.g. accuracy, speed, environmental adaptability, etc.), select the most suitable sensor model.

Areas of application:

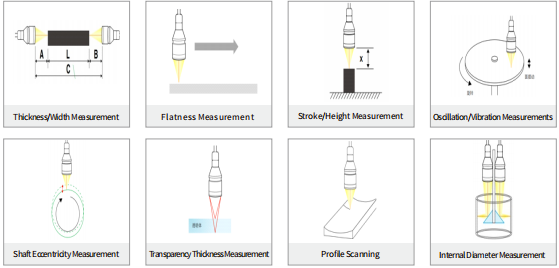

1. Metal chassis manufacturing: In the processing of metal chassis for consumer electronics products such as cell phones, tablet PCs and other consumer electronics products, spectral confocal sensors can be used to detect the flatness, thickness consistency and surface defects of the chassis to ensure product quality.

2. Electronics industry: In the production process of PCB boards, connectors, IC chips and other electronic components, spectral confocal sensors can be used to measure the height, spacing and surface morphology of components, providing data support for precision assembly and quality control.

3. Panel, glass and tempered film industry: In the production of display panels, glass products and tempered films for cell phones, spectral confocal sensors can be used to detect the thickness, curvature, flatness and other key parameters to ensure that the product meets the design requirements.

4. Semiconductor, new energy and photovoltaic industry: in the semiconductor wafer cutting, new energy cell manufacturing and photovoltaic module production process, the spectral confocal sensor's high-precision measurement ability is important to ensure product performance and improve production efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com