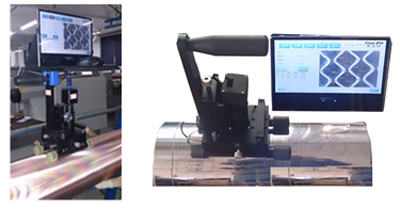

Comprehensive solution for intelligent identification and inspection of printing screen defects

Detection Points

Focusing on the precise inspection process of the raw material of the screen, our core task is to accurately identify and evaluate the many defects that may exist on the surface of the screen, including, but not limited to, weft banding, unevenly tightened or loosened areas, and any kind of creases or wrinkles. These subtle defects are directly related to the final quality and performance of the screen product.

Intelligent Vision Inspection Solution for Printing Filter

1. High-definition industrial cameras: Adopting POMEAS special Gigabit Ethernet interface industrial camera, with its excellent image capturing capability, ensures stable acquisition of high-resolution images even in high-speed production lines.

2. High-resolution lenses:Equipped with POMEAS megapixel industrial lenses, its excellent optical performance and resolution provide subtle visual insight for inspection work, ensuring that every tiny defect is invisible.

3. Light source: POMEAS ring light source, specially designed for filter surface inspection, through the optimization of light distribution, effectively eliminating shadows and reflections, so that the defect characteristics are more distinctive for subsequent image processing and analysis.

4. Intelligent industrial control platform: Equipped with I5 CPU and 4G memory as the processing core, the powerful computing power supports the complex image analysis algorithms and ensures the inspection process is smooth and unhindered.

Detection mechanism analysis

① Image Capture: A POMEAS industrial camera with PMS-5018M lens captures a comprehensive and detailed image of the screen surface to ensure that all potential defective areas are not missed.

② Image pre-processing: Pre-processing operations such as de-noising and contrast enhancement are performed on the captured image to improve the image quality and lay a solid foundation for subsequent analysis.

③ Defect identification: Using advanced image analysis algorithms, automatically identify and mark the defects on the surface of the screen, such as band weft, elastic stalls, creases, etc. The algorithms are strictly trained and optimized. The algorithm is strictly trained and optimized, featuring high sensitivity and low false alarm rate.

④ Decision Feedback: Once the defect is detected, the system will immediately trigger the alarm mechanism, and at the same time, it can control the production line to stop or adjust the parameters according to the preset rules. For non-conforming products, the system will output control signals to guide the rejection process and ensure the stability of final product quality.

⑤ Data Recording and Analysis: All inspection data and results are recorded in detail and stored in the industrial control machine, which is convenient for subsequent tracing and statistical analysis, providing powerful support for the continuous improvement of the production process.

Intelligent vision inspection solution for printing filters, with advanced machine vision technology as the core, combined with high-precision hardware equipment and intelligent algorithms, realizes comprehensive, efficient and accurate inspection of raw materials for filters. Through real-time monitoring and intelligent decision-making, it effectively improves the automation level of production line and product quality control ability.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com