High-precision PCB component automated visual inspection solutions

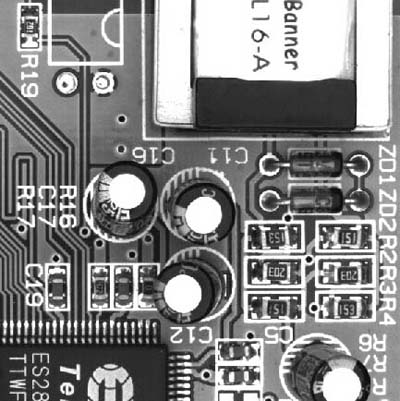

As electronic products continue to advance in the direction of miniaturization and high integration, more stringent requirements have been placed on quality control during the production process. The accurate execution of each production process is the cornerstone to ensure the performance and reliability of the final product. Among them, printed circuit board (PCB) as the core component of electronic products, its design and manufacture of each step in the process is critical. PCB design process, from the schematic drawing to the configuration of electronic components, wiring, until the final inspection, each link is closely linked to any small deviation may have a significant impact on product quality.

Given the diversity and precision of PCB components, traditional inspection methods have been difficult to meet the efficiency and precision requirements of modern production. Therefore, the introduction of high-precision PCB components automated vision inspection solution has become an industry consensus. The program can not only significantly improve the detection efficiency, but also significantly reduce the rate of misjudgment caused by human factors, to ensure the consistency and stability of product quality.

System Configuration Details

1、High-definition industrial lens:Utilizing POMEAS branded megapixel industrial lenses, it provides clear and accurate image inputs for inspections with its superior imaging quality and detail capturing ability.

2. High performance industrial camera: POMEAS Gigabit network interface 5-megapixel CCD industrial camera with high-speed data transmission capability and high sensitivity ensures stable operation even in complex light environments, capturing every subtle change.

3. light source: POMEAS ring light source, designed for PCB inspection, effectively eliminate shadows and reflections, improve image contrast, so that the detection of the target is more distinctive and easy to identify.

4. high-performance industrial computer: equipped with I5 CPU and 4G memory industrial computer, providing powerful computing power and a stable operating environment to ensure smooth operation of the inspection software, rapid and accurate data processing.

5. self-developed inspection software: based on POMEAS independent research and development of machine vision inspection software system, supports highly customized detection logic and algorithms, the user can be flexible according to the actual needs of editing the inspection project, and quickly adapt to the inspection needs of different PCB board types.

Test content and principle

- Character Detection: Automatically recognizes and compares the character information on the PCB board, accurately detects missing, misplaced and incorrect content of characters to ensure accurate information.

- Component Detection: Utilizing image processing technology, accurately identifying the presence and location of components such as capacitors and resistors, and also detecting whether the polarity of resistors is correct to prevent installation errors.

The detection principle is based on template matching and feature recognition technology. First, the standard template of each plate is established through qualified products and the corresponding detection parameters are set. When detecting, the system captures the image of the product to be inspected in real time, compares and analyzes it with the standard template, and calculates the degree of similarity or difference. Once the detection result exceeds the preset threshold, the system will automatically determine that the product is unqualified and mark the specific problem, providing clear guidance for subsequent processing.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com