Example of Precise Measurement of Telecentric Lens in Automobile Manufacturing

In the ever-changing automobile manufacturing industry, every detail is related to safety and quality, and accurate measurement is the cornerstone to ensure all this. With the wave of intelligent manufacturing sweeping the world, high-precision and high-efficiency measurement technology has become the focus of all major automotive companies. Today, let's focus on how POMEAS telecentric lenses shine in the field of precision measurement in automobile manufacturing, and become the “precision eye” that drives industrial upgrading.

A New Era of Precision Measurement

The rapid development of automobile manufacturing, especially new energy vehicles and intelligent networked vehicles, has put forward unprecedentedly high requirements on the dimensional accuracy and shape and positional accuracy of components. Traditional measurement methods are often out of their reach when facing complex surfaces, tiny structures or high-speed production lines. With its unique design principle and excellent performance, POMEAS telecentric lens opens up a new era of accurate measurement for automotive manufacturing.

Characteristics of the POMEAS telecentric lens:

1. Aberration-free, high parallelism:

With its special optical design, POMEAS telecentric lens realizes that the light rays always remain highly parallel during the imaging process, effectively eliminating image distortion due to changes in the distance of objects and ensuring the absolute accuracy of the measurement results. This is crucial for the precision measurement of key components such as automobile engine blocks, crankshafts and gears.

2. Large depth of field, wide field of view:

In the face of complex and changing measurement scenarios in automobile manufacturing, POMEAS telecentric lenses provide a wide field of view and deep depth of field, which can capture more details at once, reduce the number of lens changes, and improve measurement efficiency. Whether it's a complete vehicle assembly line or a component production line, it can be used with ease.

3. High stability and long life:

Adopting high-quality materials and precision processing technology, the POMEAS telecentric lens shows excellent mechanical stability and durability, and can operate stably for a long time even in harsh industrial environments, providing reliable measurement guarantee for automobile manufacturers.

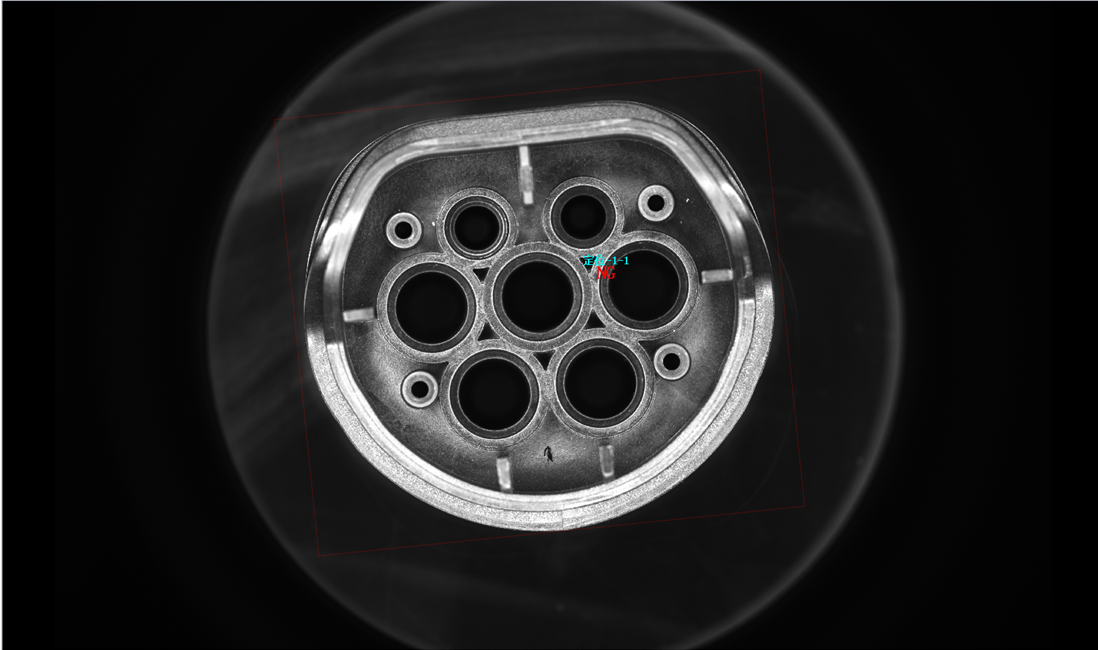

POMEAS telecentric lenses are widely used in the inspection of dimensional and form errors of engine cylinder heads, transmission gears and other key components. By combining with high-precision image processing system, it realizes instant capture and accurate positioning of tiny defects, which greatly improves product qualification rate and production efficiency. At the same time, its automated measurement process also significantly reduces the cost of manual intervention, providing strong support for the intelligent manufacturing transformation of enterprises.

In the pursuit of ultimate quality and efficiency, the POMEAS telecentric lens, with its excellent accuracy, wide adaptability and stable and reliable performance, is gradually becoming an indispensable precision measurement tool in the automotive manufacturing field. It is not only a tool to improve product quality, but also an important driving force to promote the automotive manufacturing industry to intelligent and high-end.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com