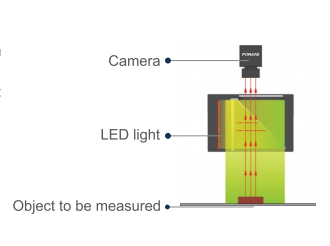

As an important type of light source in the field of machine vision, coaxial light source, with its unique design advantages and wide range of application scenarios, plays a key role in a number of fields, such as industrial automation, quality inspection, and package identification.

Advantages of coaxial light sources:

High-density arrangement of LEDs: The coaxial light source uses a high-density arrangement of LEDs as the light source, which makes the light more concentrated and uniform, effectively avoiding the generation of reflective or dazzling bright spots. This is especially important for detecting various features or defects in specularly reflected objects, as reflections and flares can seriously affect the image quality and thus reduce the accuracy of the inspection.

Flexible illumination range: Coaxial light sources are available in sizes ranging from 14x14mm to 80x80mm, and other sizes can be customized according to customer needs. This flexibility allows the coaxial light source to adapt to different sizes and shapes of inspection objects to meet diversified inspection needs.

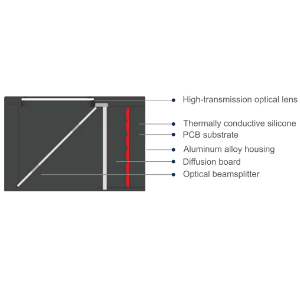

Advanced Coated Beamsplitters: Coaxial light sources equipped with advanced coated beamsplitters reduce light loss and increase light utilization. This not only makes the image brighter and clearer, but also extends the service life of the light source and reduces maintenance costs.

Unique heat dissipation structure: Unique heat dissipation structure design makes the coaxial light source can effectively dissipate heat during the working process and maintain a stable working temperature. This helps to improve the service life and stability of the light source and reduce performance degradation or damage caused by high temperature.

Aluminum PCB: The use of aluminum PCB as the substrate material of the light source can reduce the burden of significant heat on the LED array, while improving the overall heat dissipation performance. This design enables the coaxial light source to maintain a stable working condition even under a long period of high workload.

Application of coaxial light sources:

(1) Scratch Detection on Highly Reflective Surfaces: Coaxial light sources are ideal for detecting scratches on highly reflective surfaces due to their ability to minimize reflection and glare. In the surface inspection of metal, glass and other easily reflective materials, the coaxial light source can clearly present the location and shape of the scratches to improve the accuracy and reliability of the inspection.

(2) Surface inspection of easily reflective materials: In addition to scratch detection, coaxial light source is also widely used in surface inspection of various easily reflective materials (such as glass, metal, etc.). It can effectively reduce the reflection phenomenon, so that the surface defects (such as pits, bubbles, etc.) in the image more obvious, easy to follow the automated processing and analysis.

(3) Packaging barcode recognition and QR code recognition: In the packaging industry, accurate recognition of barcodes and QR codes is critical for logistics tracking and inventory management. Coaxial light source can provide uniform and stable lighting conditions, making the barcode and QR code in the image more clear and easy to read, so as to improve the accuracy and efficiency of identification. Additionally, it reduces identification errors caused by light variations or reflections.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com