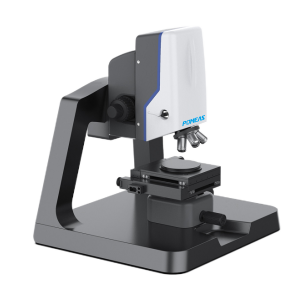

White light interferometric 3D profiler for inspection of gemstone facets

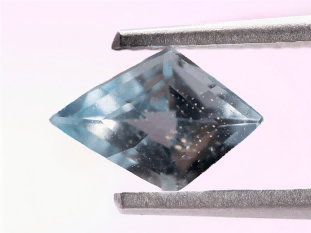

In the jewelry industry, the cut of a gemstone plays a crucial role in revealing its brilliance and value. Accurate measurement of the gemstone's cutting surface is the key to ensure the quality of workmanship and gemstone quality assessment, and this is where the White Light Interference 3D Profiler is a game changer in this field with its excellent performance.

How White Light Interference 3D Profilometer Works

The core principle of the White Light Interference 3D Profiler utilizes the phenomenon of optical interference. The broad-spectrum white light emitted by the light source is split into two beams by a beam splitter, one beam is reflected back to the gemstone cutting surface, and the other beam is reflected by a reference mirror, and the two beams of light converge again and interfere. The interference signal is received by the detector, and based on the characteristics and changes of the interference fringes, the three-dimensional topographic information of the gemstone cutting surface can be precisely analyzed, from the microscopic angular details to the overall facet structure can be clearly presented.

Measurement Advantage:

1、Ultra-High Precision: It can reach sub-micron or even nanometer measurement precision, which can accurately capture the extremely fine texture, imperfections and processing traces on the cut surface of the gemstones, and ensure that the precision of each cutting angle and plane meets the highest standards.

2、Non-contact measurement: It will not cause any physical contact or damage to the gemstones, preserving the original state of the gemstones, which is extremely important for the protection of precious and fragile gemstones.

3、Comprehensive 3D morphology analysis: It can quickly construct a complete 3D model of the gemstone's cut surface, allowing designers and appraisers to visually view the cut surface from different angles and orientations, and assess its symmetry, proportion, angle and other key indicators.

4、Efficient measurement speed: the scanning and data processing of the entire gemstone cutting face can be completed in a short period of time, which greatly improves the efficiency of detection and analysis, and meets the fast-paced needs of modern jewelry production and appraisal.

Application Scenarios:

1、Quality control in production process: In gemstone processing factories, after the workers finish the cutting process, they use white light interference 3D profiler to measure the gemstone cutting surface, so as to timely discover the problems such as cutting angle deviation and uneven surface, so as to rework and correct them in time to reduce the rate of defective products, and to improve the production efficiency and product quality.

2、Gemstone identification and grading: Appraisers can use the data measured by the instrument, such as the flatness and angle of the cut surface, combined with the color and clarity of the gemstone, to grade the gemstone more scientifically and accurately and provide a reliable basis for pricing in the market of gemstones.

3、Gemstone design optimization: When designing new gemstone cutting styles, designers use the instrument to analyze the existing successful gemstone cutting, learn from the experience, and continuously optimize the design scheme to create more perfect and brilliant gemstone cutting styles.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com