Accurate measurement of the exterior dimensions of cell phone chargers

In the high-speed production process of smartphones and their accessories, it is crucial to ensure the quality of each link. As an accessory frequently used by consumers in their daily life, the intact appearance and accurate dimensions of a cell phone charger directly affect the user experience and the overall quality of the product. In order to cope with the high efficiency and quality requirements of mass production, many manufacturers have introduced advanced in-line measurement technology at the end of the production line, especially for real-time inspection of the appearance and dimensions of cell phone chargers.

Traditional manual inspection methods are not only inefficient and difficult to achieve micron-level accuracy, especially when faced with mass production. As a result, many leading manufacturers have chosen to integrate in-line measurement systems at the end of the production line to achieve instant, accurate measurement of the dimensions of cell phone chargers. This not only dramatically improves production efficiency, but also ensures the stability and consistency of product quality.

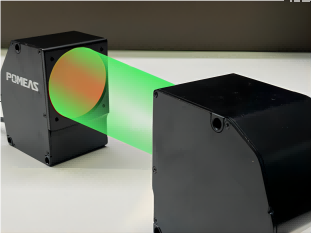

Among many in-line measurement solutions, the Image In-Line Measuring Instrument is favored for its non-contact measurement characteristics. Using a high-resolution industrial camera and advanced image processing technology, the device is able to achieve high-precision measurement of the exterior dimensions of cell phone chargers without direct contact with the product surface. This non-contact measurement effectively avoids the damage that can be caused by mechanical contact and protects the integrity of the charger's surface, while capturing extremely small dimensional deviations.

To meet the stringent requirement of less than 1um dimensional error for cell phone chargers, the Image In-Line Measuring Instrument achieves micron-level measurement accuracy through sophisticated algorithms and calibration procedures. This means that any minor dimensional deviations can be detected and corrected in time during the production process, thus ensuring that every cell phone charger meets or exceeds the design standards and provides consumers with a superior user experience.

To further improve production efficiency and quality management, many manufacturers have also established an intelligent management system based on big data analysis. The system is able to collect and process measurement data from on-line gauges in real time, and analyze the size distribution, change trends and potential quality problems of products through intelligent algorithms. Once abnormal data or non-conforming products are found, the system will automatically trigger an alarm mechanism and give corresponding processing suggestions, helping manufacturers make quick decisions, reduce losses and improve overall production efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com