In the driveshaft machining industry, the precise measurement of product dimensions is a key component to ensure product quality and performance. However, in the face of micron-level (0.1μm) measurement accuracy requirements, traditional measurement tools such as calipers, micrometers, etc. are not only inefficient, but also prone to damage the surface of precision machined drive shafts due to contact measurement, which in turn affects the overall quality and service life of the product.

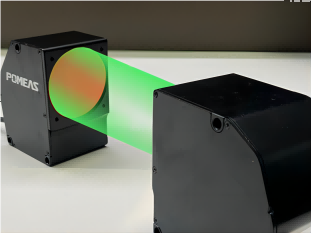

In order to solve this challenge, POMEAS In-Line Image Gauge provides an innovative solution for high-precision in-line measurement of drive shafts with its advanced telecentric optics and non-contact measurement technology.

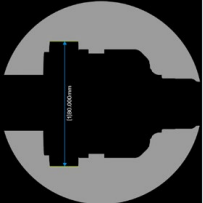

High precision telecentric optical system

The telecentric optical system used in the POMEAS In-Line Image Gauge effectively eliminates measurement errors caused by changes in position or tilting of the object to be measured, ensuring stability and accuracy of the measurement results. The system is designed for high-precision measurements and maintains excellent measurement performance even in complex and changing processing environments.

Non-contact measurement

By capturing image information of the drive shaft surface with a high definition image sensor, the integrity of the product surface is protected by avoiding scratches or indentations that may be caused by traditional contact measuring tools. The non-contact measurement method not only improves measurement efficiency, but also significantly reduces the rate of defective products caused by measurement.

Automated on-line measurement

The measuring instrument supports automation integration and can seamlessly connect to the production line to realize online real-time measurement of drive shafts. Data acquisition, processing and analysis are automatically completed through pre-set measurement procedures and algorithms, greatly improving production efficiency and reducing manual intervention and errors.

Powerful software

Equipped with professional measuring software, it supports a variety of measuring modes and data processing functions, such as dimensional measurement, shape and location tolerance evaluation, contour analysis, etc.. Users can flexibly set the measurement parameters according to the actual needs, and quickly obtain accurate measurement results and detailed measurement reports.

Easy to operate and maintain

POMEAS online image measuring instrument adopts humanized design, the operation interface is simple and intuitive, easy to get started. At the same time, the equipment is simple to maintain, reducing the operating costs of the enterprise.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION