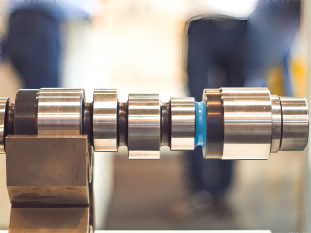

Efficient Measurement Technique for Camshaft Journal-to-Jacket Outside Diameter

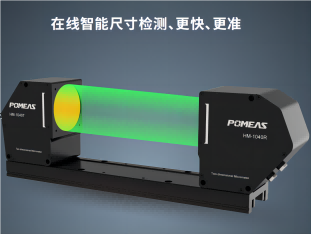

In the field of precision machinery manufacturing, especially for the measurement of long and complex workpieces such as camshafts, traditional methods often face challenges such as inefficiency and lack of accuracy. Modern in-line image measuring instruments, through their advanced technological innovations, have realized efficient and accurate measurement of such workpieces, especially for the outer diameter dimension between the journals, providing an unprecedented solution.

Core strengths:

1, sliding measurement technology: for long workpieces such as camshafts, the online image measuring instrument adopts sliding measurement technology, which can carry out continuous and uninterrupted measurement along the length of the workpiece. This technology not only improves the measurement efficiency, but also ensures the integrity and continuity of the measurement data, providing a reliable basis for subsequent quality control.

2, multi-position comprehensive judgment: due to the possible differences between the various parts of the long workpiece, the measuring instrument will divide the workpiece into a number of key positions for measurement. The measurement image and project of each position can be set independently, and the overall evaluation result is finally obtained by comprehensively judging the data of each position. This divide-and-conquer strategy greatly improves the accuracy and comprehensiveness of the measurement.

3, flexible processing modes: in order to adapt to the measurement needs of different positions, the measuring instrument is built-in a variety of processing modes. Users can preset up to 8 different processing modes in one program to meet the needs of different measurement projects. When the measurement signal is triggered, the system will automatically switch to the corresponding processing mode to achieve high-speed, seamless switching to ensure the smoothness and efficiency of the measurement process.

4, intelligent automatic switching function: in the mixed flow production line or the need to randomly measure a variety of workpiece environment, the automatic switching function of the measuring instrument is particularly important. The system through advanced image recognition technology, can automatically identify the shape of the workpiece, and accordingly automatically switch to the corresponding measurement processing mode. This function not only simplifies the operation process and reduces the need for manual intervention, but also significantly improves the flexibility and productivity of the production line.

5, efficient and convenient operation experience: the entire measurement process without manually entering the variety of switching signals or commands, greatly reducing the burden on the operator. At the same time, the measuring instrument provides an intuitive, easy-to-understand user interface and a wealth of data reporting capabilities, making it easier and faster to view and analyze the measurement results.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com