In industrial production, the dimensional measurement of drive shafts is a critical step to ensure product quality and performance. In this paper, an efficient and accurate measurement method is presented, which utilizes advanced laser in-line measuring technology and a POMEAS telecentric optical system to achieve a comprehensive measurement of drive shafts up to ø120 mm in diameter, demonstrating the excellence of modern measurement technology.

Simplify operations and improve efficiency

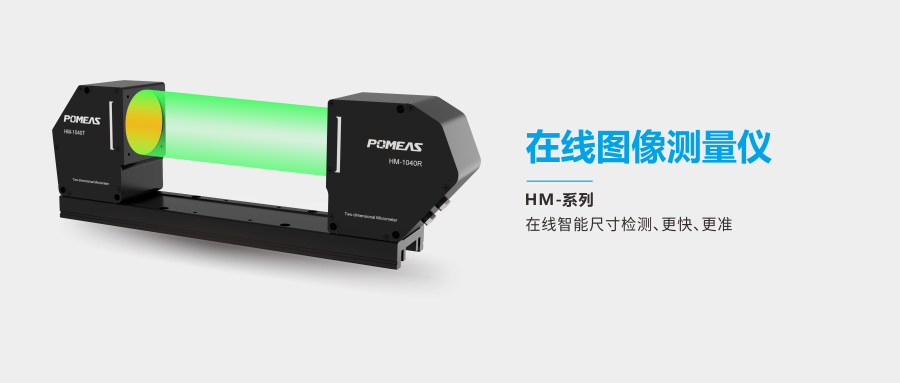

The traditional multi-measuring head solution is flexible, but often accompanied by complex operation processes and maintenance costs. The measurement program in this case, on the other hand, requires only 1 laser on-line measuring instrument to perform the task, which greatly simplifies the measurement process and improves work efficiency. This not only reduces the requirements for operator skills, but also reduces the errors that may occur due to multiple components working together, ensuring the stability and reliability of the measurement results.

POMEAS Telecentric Optical System, Guarantee of High Accuracy Measurement

The POMEAS telecentric optical system is one of the core technologies of this measurement solution. The system is uniquely designed to achieve high precision measurements without the need for tedious fine adjustments. The design principle of telecentric lens effectively eliminates the measurement error caused by the change of the distance between the lens and the object to be measured, ensuring the accuracy of the measurement data. At the same time, the system is also characterized by high speed, large depth of field and low noise, making the measurement process smoother and the results clearer and more accurate.

The perfect combination of high speed, large depth of field and low noise

High speed, large depth of field and low noise are the three key indicators in driveshaft dimensioning. This measurement solution successfully realizes the perfect combination of these three through the application of the POMEAS telecentric optical system. The short exposure time ensures high-speed measurement, even on fast production lines; the large depth of field allows the measuring head to easily handle different heights and angles of the drive shaft surface without frequent focus adjustments; and the low-noise projection image further improves the clarity and accuracy of the measurement, making the results more reliable.

Immediate application without tedious adjustments

The measurement solution has been rigorously tuned and calibrated before leaving the factory to achieve the ideal condition. Users can put it into various application scenarios immediately after purchase without having to make complicated fine adjustments. This not only saves users a lot of time and effort, but also avoids measurement errors and losses caused by improper commissioning.

With its high efficiency, accuracy and ease of use, the laser on-line measuring instrument provides strong technical support for the measurement of drive shafts in industrial production, improving production efficiency, reducing maintenance costs and ensuring product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com