Automotive parts production line measurement equipment application cases

In the automotive manufacturing industry, the precision and consistency of components are directly related to the performance, safety and user experience of the entire vehicle. Therefore, quality control on the production line is particularly important. As an efficient and accurate measurement solution, in-line measuring instrument is gradually becoming the standard equipment in automotive parts production line, especially in the final inspection, its role is indispensable.

In order to improve production efficiency and product quality, automobile manufacturers have decided to introduce advanced in-line measuring instruments into the production lines of their key components (e.g. engine blocks, crankshafts, brake discs, etc.). The precision of these components is extremely high, and any small dimensional deviation may have a significant impact on vehicle performance. The traditional offline sampling method can no longer meet the demand for rapid and comprehensive quality control, so the implementation of online measurement has become an inevitable choice.

On the automaker's production line, in-line gauges are installed after the last process, before the finished product rolls off the line. When a part passes through the production line and reaches the measuring station, the gauge is automatically activated to scan or contact measurements of critical dimensions of the part in all directions. The measurement data is immediately compared with the preset standard values. If the dimensional deviation is within the permissible range, the part is regarded as qualified and continues to the next stage; if it exceeds the permissible range, an alarm mechanism is automatically triggered, and the defective part can be automatically rejected or reworked.

Online measuring instrument also has a powerful data analysis function, can real-time statistics in the production process of dimensional deviation, for the production management personnel to provide intuitive quality trend charts, to help them quickly identify potential problems in the production process, and take corrective measures in a timely manner to ensure that the product quality is stable and reliable.

Advantages of the application of on-line measuring instruments:

Real-time: The in-line measuring instrument can detect the size of each part in the production process in real time, ensure that each process meets the quality requirements, detect and correct deviations in time, and reduce the flow of defective products into the next process.

High precision: using advanced laser, optical or contact measurement technology, the in-line measuring instrument can achieve micron or even nanometer measurement accuracy, to meet the extremely high precision requirements of automotive parts.

Automation: Seamless integration with the production line realizes automated measurement, reduces manual intervention, and improves measurement efficiency and accuracy. At the same time, through automatic data collection and analysis, it provides powerful support for production decision-making.

Traceability: The measurement data of each part can be recorded and traced, which facilitates the analysis and improvement of quality problems and improves the overall quality management level.

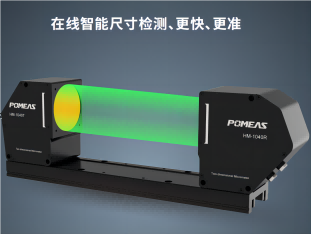

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com