In the photovoltaic (PV) industry, efficient and accurate detection of various defects in PV modules, such as breakage, contamination, and junction box problems, has been a major challenge for manufacturers. These difficulties not only affect product quality, but also may pose a threat to the long-term operational safety of power plants. In order to effectively solve these difficulties, POMEAS has introduced an advanced 3D line scan laser profile sensor measurement system, which revolutionizes PV module inspection.

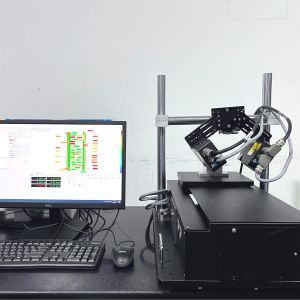

The POMEAS 3D Line Scan Laser Profile Sensor Measurement System integrates a high-precision 3D Line Scan Laser Profile Sensor with the MetX measurement system control software, realizing fast and comprehensive capture of 3D coordinate information on the surface of photovoltaic modules. The system is capable of accurately identifying and quantifying various defects on the module surface, including subtle cracks, stains, and junction box assembly issues, greatly enhancing the efficiency and accuracy of the inspection and effectively avoiding the occurrence of missed inspections.

Advantages of the POMEAS 3D Line Scan Laser Profile Sensor Measurement System:

Multi-sensor cooperative operation: The system supports simultaneous matching of multiple line-scan sensors, which are controlled by the 3DOS measurement system to realize simultaneous acquisition of multi-product data at different angles and in different states. This design greatly expands the inspection range and ensures the comprehensiveness and integrity of the data.

Efficient Data Processing Capability: The ability to quickly integrate point cloud data from multiple sensors for overall processing. This not only improves scanning and processing capabilities for products with complex shapes and structures, but also significantly improves inspection efficiency, providing strong support for rapid inspection of large-scale production lines.

Comprehensive Inspection Functions: It not only meets the basic dimensional inspection needs of PV modules, such as height, segment difference, flatness, coplanarity, contour, etc., but also realizes advanced functions, such as appearance inspection and surface feature tracking. The integration of these functions enables the system to assess the quality of PV modules in an all-round and multi-angle manner.

Improve product quality and safety: With accurate inspection and timely feedback, the 3D Line Sweep Laser Profile Sensor measurement system helps manufacturers to identify and fix potential problems with PV modules in a timely manner, which significantly improves the quality of the product and the safety of the power plant's operation.

With its excellent performance and comprehensive inspection capabilities, the POMEAS 3D Line Scan Laser Profile Sensor Measurement System provides an innovative solution to PV module inspection challenges. It not only improves inspection efficiency and accuracy, but also pushes the PV industry towards higher quality and safety.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com