In modern industrial production, quality inspection is a key link to ensure product quality. With the progress of science and technology, the application of laser sensors is becoming more and more widespread, especially in the cylindrical metal parts of the external dimensions and the appearance of defects detection, showing unparalleled advantages

Basic principles of laser profile sensors:

The laser profile sensor utilizes the high directionality and high brightness characteristics of the laser beam to realize the accurate measurement of the object by means of a precise photoelectric conversion device. Its working principle mainly includes three parts: laser transmission, reception and signal processing.

Advantages of laser profile sensors:

High Accuracy: Laser profile sensors can detect with an accuracy of up to 0.005mm, meeting the most stringent production standards.

High speed: Due to the fast response characteristics of the laser, the detection speed is extremely fast and suitable for in-line inspection of mass production.

Non-contact measurement: Avoiding the damage to parts and wear and tear of equipment that may be caused by traditional contact measurement.

Application of laser contour sensors in the inspection of cylindrical metal parts

1. Diameter Inspection: The diameter of a cylindrical metal part is an important parameter that affects its functionality and assembly performance. By scanning the cylindrical surface, the laser sensor calculates the diameter data in real time, ensuring that each part is within the specified tolerances.

2. Height Detection: Height detection is equally critical to ensuring part quality. The laser profile sensor accurately measures the height of the part by scanning vertically to ensure that it meets the design requirements.

3. Appearance Defect Detection: Appearance defects such as scratches and pits not only affect the aesthetics of the part, but can also pose a potential threat to its performance. Laser sensors are able to detect minor defects and ensure product quality through high-resolution image acquisition and analysis.

The application of laser contour sensors in the inspection of cylindrical metal parts demonstrates the great potential of modern technology to improve the quality and efficiency of production. Through high-precision diameter and height detection as well as the detection of cosmetic defects, laser sensors provide a powerful guarantee for production in various industries.

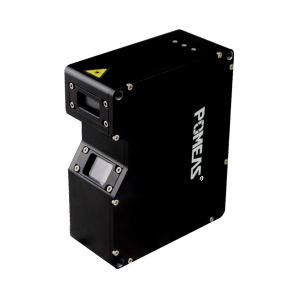

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION