How to choose the right measurement sensor in machine vision inspection?

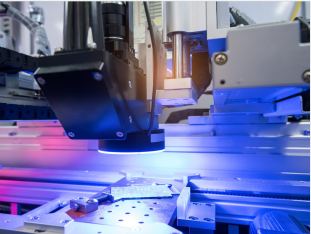

In the field of machine vision inspection, measurement sensors play a crucial role. They are key devices for acquiring information about objects, which directly affects the accuracy, precision and efficiency of inspection.

A suitable measurement sensor can accurately capture the characteristics of the inspected object, such as size, shape, position, color, etc., providing a reliable data base for subsequent image processing and analysis. Through accurate measurement, product defects and deviations can be detected in time to ensure that product quality meets standards, improve production efficiency, reduce costs and enhance the market competitiveness of enterprises.

So, how to choose the right one among the many measurement sensors?

1. Define the requirements: The specific requirements of the inspection task need to be defined. This includes the characteristics of the object to be detected, such as material (whether metal, plastic, glass or other), surface condition (smooth, rough, transparent, etc.), shape and size range. Also consider the accuracy requirements of the inspection, whether you need high precision micron-level measurement, or relatively low precision millimeter-level measurement.

2. Environmental factors: Factors of the inspection environment are to be considered. For example, ambient temperature, humidity, the presence of dust, oil, electromagnetic interference, etc. These factors may affect the performance and stability of the sensor.

3. Sensor performance parameters: focus on the performance parameters of the sensor. Such as the measurement range, to ensure that the sensor's measurement range can cover the size change of the detected object. Resolution determines the minimum amount of change that the sensor can distinguish, especially important for high-precision detection. Response speed affects the efficiency of detection, especially in high-speed production lines.

4. Stability: the stability and reliability of the sensor is also a key factor. Choose brands and products with good reputation and quality assurance to reduce failure and maintenance costs.

5. System compatibility: Consider the compatibility and integration of the sensor with the entire machine vision system. Ensure that the sensor can work seamlessly with other components such as image processing software, control system, etc. to realize efficient data transmission and cooperative work.

In choosing the right measurement sensor need to consider the inspection task requirements, stability, system compatibility and other factors, only in this way can ensure the accuracy and efficiency of the machine vision inspection system.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION