Application of Laser Alignment Measuring Instrument in Mobile Phone Camera Module

Under the background of rapid development of modern science and technology, laser alignment measuring instrument, as a high-precision measuring tool, has been widely used in various fields. Especially in the manufacturing process of cell phone camera module, laser alignment measurement instrument plays a vital role. So, what is laser alignment gauge? And how is it applied to cell phone camera modules?

What is Laser Alignment Gauge?

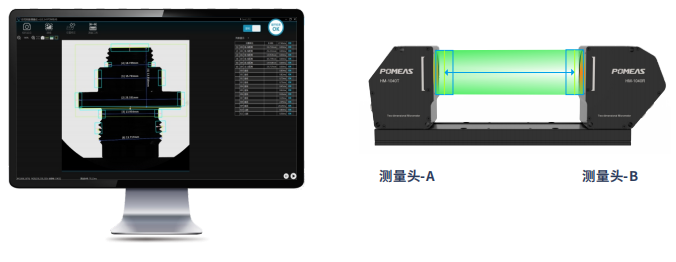

A laser alignment gauge is a device that utilizes a laser beam to make precise measurements. It calculates the distance, position and other information of the target object by emitting the laser beam and receiving the signal reflected back. This type of measurement has the advantages of high precision, fast response, non-contact measurement, etc. It is widely used in industrial automation, robot navigation, building mapping and other fields.

Application of laser alignment measurement in cell phone camera modules:

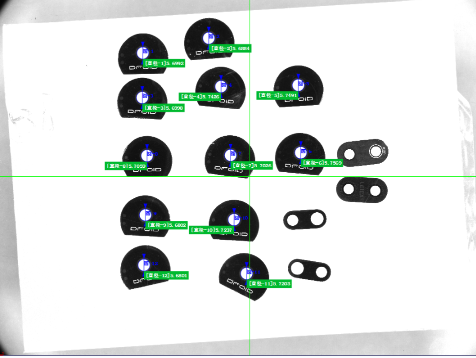

Basic Composition of Mobile Phone Camera Module The cell phone camera module is mainly composed of lenses, image sensors, motors, filters and so on. The precision and degree of coordination of each component directly affects the final imaging quality. Therefore, these components need to be precisely measured and adjusted during the manufacturing process.

Specific applications of laser alignment gauges:

1. Alignment and focusing of the lens: During the installation of the lens, the laser alignment meter can monitor the position and angle of the lens in real time to ensure its precise alignment with the image sensor. This not only improves the imaging quality of the camera, but also reduces the scrap rate in the production process.

2. Positioning of the image sensor: the image sensor is one of the core components of the cell phone camera. The laser alignment measuring instrument can ensure the performance of the camera by accurately measuring the position of the sensor to ensure that it will not be offset during the manufacturing process.

3. Precise control of motor: The motor is used to drive the lens to move and realize the auto-focus function. The laser alignment meter can monitor the movement status of the motor in real time to ensure that it moves in the correct range, which improves the speed and accuracy of autofocus.

4. Filter installation: The function of the filter is to filter out unnecessary light and improve the imaging quality. The laser alignment meter can accurately measure the position and angle of the filter to ensure that it can be correctly installed in the camera.

Advantages of Laser Alignment Measurement:

High precision: laser alignment measuring instrument adopts advanced laser technology, which is able to measure accurately within the micron level, meeting the extremely high precision requirements of cell phone camera modules.

Fast response time: traditional measurement methods often take a long time to get the results, while the laser alignment measuring instrument can complete the measurement in a short period of time, which greatly improves the production efficiency.

Non-contact measurement: laser alignment measuring instrument does not need to be in direct contact with the target object, avoiding damage and contamination due to contact, especially suitable for the measurement of precision components.

High degree of automation: laser alignment measuring instrument can be seamlessly integrated with other automation equipment to realize fully automatic measurement and adjustment on the production line, which reduces manual intervention and improves the consistency and stability of production.

The application of laser alignment measuring instrument in the manufacturing process of cell phone camera module not only improves the quality and performance of the product, but also greatly improves the efficiency and reliability of production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com