Application of Laser Alignment Measuring Instrument in Battery Dimension Measurement

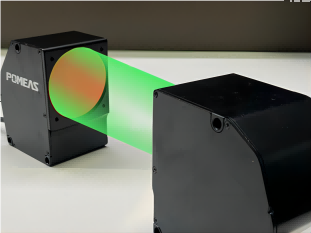

As a high-precision, non-contact measurement tool, the laser alignment measuring instrument shows unique advantages in the field of cell size measurement.

Working Principle of Laser Alignment Measurement:

Laser alignment gauges work on the principle of transmitting and receiving a laser beam. When a laser transmitter sends out a laser beam, a receiver is located at the other end to receive the laser signal. If the laser beam is blocked or if there is any change in the path, the receiver will not be able to receive the complete laser signal, thus triggering an alarm or a measurement signal. This working principle makes the laser countermeasure have the advantages of long detection distance, low false alarm rate, strong anti-interference, strong prevention and wide adaptability.

Characterization of Laser Alignment Measuring Instruments for Cell Dimensioning

Highly Accurate Measurements: Laser alignment gauges provide highly accurate measurements, which are critical for cell manufacturing processes that require precise dimensional control. For example, when measuring the thickness, length and width of a cell, laser alignment gauges ensure accurate and reliable data.

Non-Contact Measurement: Laser Alignment Gauges utilize a non-contact measurement method that avoids the physical damage or contamination that can be caused by traditional measurement tools. This is especially important in application scenarios where the integrity and cleanliness of the cell surface needs to be maintained.

Adaptable: Whether it is a soft pack battery or other types of batteries, the laser alignment meter can be adapted to different measurement needs by adjusting the measurement parameters and settings. At the same time, its large spot size (e.g. 30×1100um) can effectively cover the roughness characteristics of the battery surface, avoiding the data fluctuation problem caused by single-point measurement.

Efficient Measurement: The laser alignment measuring instrument can realize fast and continuous measurement, which greatly improves the production efficiency. This feature is particularly important in battery production lines, as it ensures that each cell is subjected to rigorous dimensional inspection, thereby improving product quality and consistency.

Laser alignment gauges are used for dimensional measurements in the cell manufacturing process in the following areas:

-

Battery Thickness Measurement:Using a laser thickness gauge or similar device, the thickness of a cell is accurately measured by scanning the surface height value of the cell. This method is particularly suitable for cell types such as flexible pack batteries that require a fixed pressure to be applied for measurement.

-

Battery length and width measurement:Accurate measurement of the length and width of the cell can be achieved using conventional tools such as straightedge, tape measure or digital calipers in combination with a laser alignment gauge. During the measurement process, it is necessary to keep the tool perpendicular to the surface of the cell to avoid deviations.

-

Battery Overall Dimension Inspection:Through the combined application of laser alignment measurement and other measurement tools, the overall dimensions of a cell can be thoroughly inspected. This helps to ensure that the cell meets design requirements and customer needs, while increasing product competitiveness in the marketplace and customer satisfaction.

With the characteristics of high accuracy, non-contact, adaptability and efficient measurement, POMEAS Laser Alignment Measuring Instrument has shown great potential in the field of battery size measurement. With the expansion of new energy vehicle market and the continuous progress of power battery technology, laser alignment measurement instrument will provide more reliable and efficient technical support for battery manufacturing process.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com