Sensors play a crucial role in the development of modern technology. They serve as a bridge between the physical and digital worlds, helping us to access a wide range of environmental information. Today, we will take an in-depth look at the classification of sensors, specifically the two main categories of measurement sensors: contact and non-contact.

I: Contact measurement sensors

Contact measurement sensors acquire data by directly contacting the object to be measured. These sensors are widely used in industrial manufacturing, medical devices, and other fields. Their main advantages include high accuracy and real-time feedback. For example, in machining processes, contact sensors can monitor the wear and tear of tools in real time, thus improving productivity and product quality.

II: Non-contact measuring sensors

Unlike contact sensors, non-contact measurement sensors do not need to be in direct contact with the object to be measured, but instead measure it by means of optics, electromagnetic waves, and other means. This type of sensor is particularly common in the field of machine vision due to its greater flexibility and safety.

Measurement Sensor Usage:

1. Product observation: Non-contact measurement sensors play an important role in product observation. Through cameras and other optical sensors, the system can monitor the product quality on the production line in real time, identify defects and take timely action. This approach not only improves production efficiency, but also reduces the occurrence of human error.

2. 2D Dimensional Measurement: Non-contact sensors also excel when it comes to 2D dimensional measurement. Utilizing optical principles, these sensors can quickly and accurately measure parameters such as the length and width of an object. Compared to traditional contact measurement methods, non-contact measurement not only avoids damage to the surface of the object, but also greatly improves the measurement speed.

3. 3D Contour Inspection: D contour inspection is an important application in machine vision and an advantage of non-contact measurement sensors. Through laser scanning, stereo vision and other technologies, the system can obtain the three-dimensional contour information of the object, so as to achieve more accurate detection and analysis. This method is widely used in automotive manufacturing, electronic component inspection and other fields.

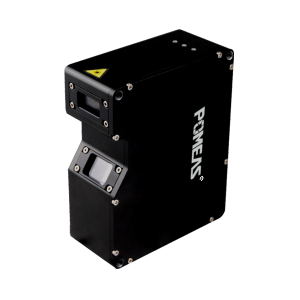

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION