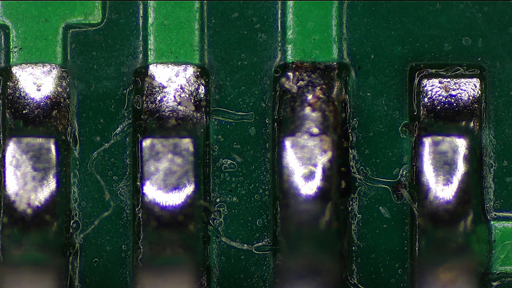

White Light Interferometry Solutions for Surface Topography of Circuit Boards

In modern electronics manufacturing, the quality and performance of circuit boards are critical. Accurate measurement of circuit board surface topography is one of the key aspects in assessing its quality and reliability. White light interferometry, as a high-precision, non-contact measurement means, provides an effective solution for the measurement of circuit board surface topography.

Principles of white light interferometry

White light interferometry is based on the principle of light interference. When a beam of white light is incident on the measured surface, the reflected light produces interference fringes due to the microscopic undulations of the surface. By analyzing and processing the interference fringes, the height information of the surface can be obtained to construct a three-dimensional image of the surface topography.

Compared to conventional measurement methods, white light interferometry has extremely high vertical resolution (down to the nanometer scale) and lateral resolution, and is able to accurately capture minute features and defects on the surface of circuit boards.

Measurement system components

1、Light Source: Provides a broad spectrum of white light to ensure that clear interference fringes are produced at different wavelengths.

2、Interference optical path: Interferes with incident and reflected light to form interference fringes.

3、Detector: Used to receive the optical signals of the interference fringes and convert them into electrical signals.

4、Data Acquisition and Processing Unit: collects and processes the electrical signals output from the detector to calculate the height information of the surface.

5、Motion control platform: realizes the precise movement and positioning of the measured circuit board to ensure the integrity and accuracy of the measurement.

Measurement process

①. Sample Preparation: The circuit board to be measured is cleaned and treated to remove dust and impurities from the surface to ensure the accuracy of the measurement results.

②. System Calibration: Before measurement, the measurement system needs to be calibrated, including optical path calibration, detector sensitivity calibration, etc. to eliminate system errors.

③. Measurement Setting: Set parameters such as measurement range, resolution, scanning speed, etc. according to the size of the board and measurement requirements.

④. Data Acquisition: Start the measurement system, scan the surface of the circuit board and collect the interference fringe data.

⑤. Data Processing: use professional software to process and analyze the collected data, remove noise, fit the surface topography, calculate surface roughness and other parameters.

Advantages in circuit board measurement

1. High accuracy: capable of providing nanometer-level measurement accuracy to meet the requirements of circuit boards for high-precision measurement of surface topography.

2. Non-contact measurement: avoids damage and contamination to the circuit board surface, and does not introduce the influence of measuring force on the measurement results.

3. Fast measurement: Compared with traditional measurement methods, the measurement speed is faster, which can greatly improve production efficiency.

4. Multi-parameter Measurement: Not only can we measure the surface roughness, but we can also obtain a variety of parameters such as surface profile, step height, line width, and so on.

As an advanced measurement method, POMEAS white light interferometry technology provides a high precision, non-contact, fast and multi-parameter solution for the measurement of circuit board surface topography. Its application in the electronics manufacturing industry will help to improve the quality and performance of circuit boards and promote the development and innovation of the industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com