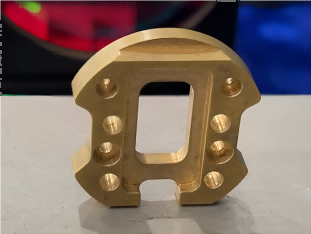

In the production and quality inspection of hardware, it is crucial to accurately measure its contour, axial curvature and surface flatness. However, due to the variety of shapes and high dimensional accuracy requirements of hardware, inspecting its contour faces many challenges.

The difficulty of hardware contour inspection is mainly reflected in the following aspects:

1、Hardware has a complex shape and may contain various curves, surfaces and irregular geometric features, which makes it difficult for traditional measurement methods to comprehensively and accurately obtain its contour information.

2、Hardware often requires a high degree of dimensional accuracy, and small errors can affect its performance and assembly, so measuring instruments are required to have extremely high resolution and accuracy.

3、Hardware is made of a variety of materials with different surface characteristics, such as different reflectivity and roughness differences, which makes light reflection and data acquisition during the measurement process difficult.

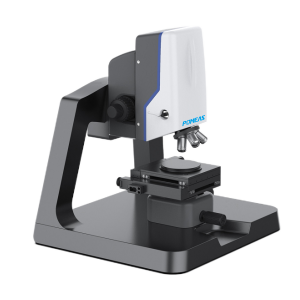

The POMEAS white light interferometer provides an excellent solution to the difficult problem of hardware profile measurement with the following remarkable measurement features:

-

Ultra-high precision: capable of realizing nanometer-level measurement precision, meeting the demanding requirements of hardware for dimensional accuracy, and accurately measuring minute contour changes and surface roughness.

-

Non-contact measurement: avoids direct contact with the surface of the hardware, preventing damage to the measured part and reducing the introduction of measurement errors.

-

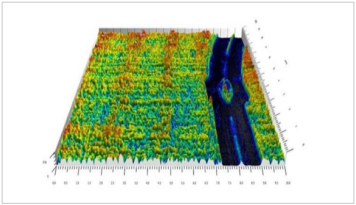

3D Contour Imaging: It can quickly obtain the 3D contour image of the hardware, intuitively displaying its overall shape and detailed features, helping inspectors to fully understand the shape of the tested part.

-

Large measuring range: Suitable for different sizes of hardware, from tiny parts to larger components, all can be measured effectively.

-

Adaptability to different materials and surface characteristics: The optimized optical system and measurement algorithms enable accurate and stable data to be obtained on a wide range of hardware surfaces.

-

Automated Measurement: Equipped with advanced control system, it can realize automated measurement and data acquisition, improve measurement efficiency and reduce human error.

With its high-precision, non-contact, 3D imaging and other measurement features, the POMEAS white light interferometer effectively solves the problem of hardware contour inspection, and provides powerful support for quality control and product optimization in the hardware industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION