Efficient measurement of cell phone camera size on production line

With the increasing competition in the smartphone market, the performance and quality of cell phone cameras have become the focus of competition among major manufacturers. The accuracy of the camera module is directly related to the imaging quality, so the dimensional measurement of the camera parts has put forward extremely high requirements.

Difficulties in measuring cell phone camera parts:

1. Complex and variable dimensions: cell phone cameras usually contain multiple precision components such as lenses, sensors, circuit boards, etc., each of which has different dimensions and shapes, and needs to maintain very high positional accuracy and coaxiality after assembly.

2. Multiple dimensional measurement requirements: not only is it required to measure the basic dimensions such as lens diameter, height, thickness, etc., but it is also necessary to accurately measure key parameters such as the distance between the lens and the sensor, and the tilt of the lens.

3. High precision, small tolerance: due to the huge impact of the camera on the imaging quality, its size measurement accuracy needs to reach the micron level, any small deviation may lead to a decline in imaging effect.

4. Line automation requirements: in order to meet the needs of efficient production, the measurement process needs to be integrated with the production line automation system to achieve rapid and continuous measurement operations.

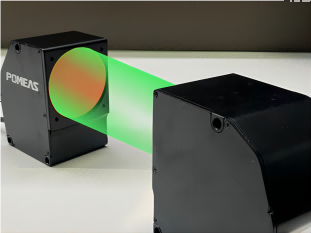

Advantages of the application of the POMEAS In-Line Image Measuring Instrument:

High-precision image acquisition and processing:

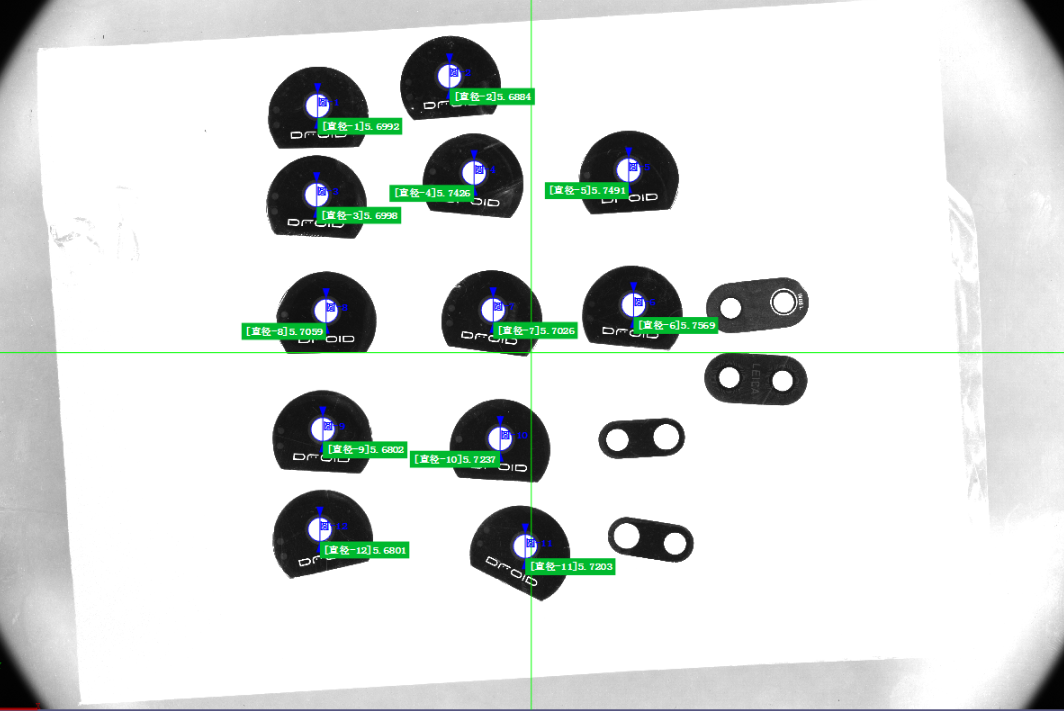

① POMEAS online image measuring instrument adopts high-resolution camera and advanced optical system, which can clearly capture the micro-features of camera parts and ensure the accuracy of measurement data.

② Equipped with professional image processing algorithms, it can automatically identify and extract key dimensional information to reduce human error.

Versatile measurement software:

① The software interface is friendly and supports a variety of measurement modes and programming functions, which can be customized according to different camera parts to achieve one-key measurement.

② real-time display of measurement results, automatic data analysis and comparison, rapid identification of nonconforming products, improve production efficiency.

Highly automated integration:

① POMEAS online image measuring instrument can be integrated with the production line automation system to realize automatic loading and unloading, positioning, measuring and sorting functions without human intervention.

② Support remote control and monitoring, which is convenient for managers to grasp the real-time status of the production line and adjust the production plan in time.

Efficient, stable and adaptable:

① High-speed measurement capability dramatically increases line throughput to meet the demands of mass production. Adaptability to

② Good adaptability to different models and specifications of camera parts, eliminating the need for frequent changes in measuring tools and calibration.

With its high accuracy, versatility and high automation, POMEAS in-line image measuring instrument has shown significant advantages in the field of cell phone camera parts measurement. It not only solves many problems of traditional measurement methods, but also promotes the intelligence and automation process of cell phone manufacturing industry. In the future, with the continuous progress of technology and the expansion of application scenarios, PMIS online image measuring instrument will play an important role in more fields and help enterprises realize high-quality development.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com