Principle of copper foil thickness measurement by spectral confocal technique

Spectral confocal technology is an imaging technique that combines an optical confocal microscope with a spectrometer, which utilizes the three-dimensional imaging capability of the confocal microscope and the spectral analysis capability of the spectrometer to simultaneously acquire information such as the sample's topography and optical properties.

Introduction to spectral confocal techniques:

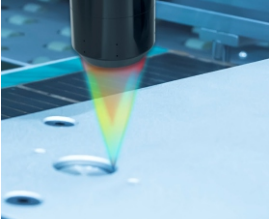

Spectral confocal technology uses spectral analysis to determine the position or thickness of an object by illuminating the object under test with a laser beam and receiving the reflected light. Specifically, the technique uses a color laser light source to emit a beam of high-density broad-spectrum light, which, after passing through a dispersive lens, forms monochromatic light of different wavelengths within the range, with each wavelength corresponding to a specific distance value. When this monochromatic light hits the surface of the copper foil and is reflected back, only the light that meets the confocal conditions can pass through the small aperture and be sensed by the spectrometer. By calculating the focal wavelength of the detected light, the thickness of the copper foil can be converted.

Principle of measuring the thickness of copper foil:

Laser beam emission and reception: The spectral confocal sensor emits a laser beam containing several wavelengths, which passes through the copper foil and is reflected on its upper and lower surfaces.

Spectral analysis and calculation: The reflected light is received by the sensor and analyzed by a spectrometer. The spectrometer breaks down the light signal into different wavelengths and records the intensity of light at each wavelength. Since different wavelengths of light focus at different positions on the upper and lower surfaces of the copper foil, the thickness of the copper foil can be inferred from the spectral information.

Data processing and calibration: In order to obtain accurate copper foil thickness values, the spectral data needs to be processed and systematic errors eliminated by a calibration procedure. The calibration process usually involves comparison with a standard sample of known thickness to ensure the accuracy of the measurement results.

The POMEAS spectral confocal technique for measuring copper foil thickness has the advantages of non-contact, high accuracy, on-line measurement, and no need for radiation licensing. It avoids the surface damage and measurement errors that may be caused by traditional contact measurement methods, while realizing real-time and continuous thickness monitoring. Spectral confocal technology has been widely used in the fields of electronics manufacturing and materials science, providing an efficient and reliable solution for thickness measurement of thin film materials such as copper foil.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com