Differences in application scenarios between telecentric and industrial lenses

Telecentric lens imaging principle:

Telecentric Lens is designed to correct the parallax of traditional lenses. It is through a specific optical path design, so that in a certain object distance range, the magnification of the image will not change with the distance of the object from the lens, thus avoiding the common “near big far small” phenomenon of traditional lens imaging. Telecentric lens mainly includes the object-side telecentric lens, image-side telecentric lens and bilateral telecentric lens.

-

Object-side telecentric lens: The aperture diaphragm is placed on the focal plane of the image-side of the optical system so that the main light rays of the object-side are parallel to the optical axis and the convergence center of the main light rays is located at infinity on the object-side. In this way, the magnification of the image remains constant no matter how the distance of the object from the lens changes.

-

Image-square telecentric lens: the opposite of the object-square telecentric lens, the aperture diaphragm will be placed in the optical system of the object-square focal plane, so that the image of the main light parallel to the optical axis, the main light convergence center is located in the image of the infinite distance. It is characterized by magnification is independent of the image distance, the camera installation position of the distance does not affect the imaging effect.

-

Bilateral telecentric lens: combining the dual role of object-side telecentric and image-side telecentric, the object and the camera position of the near and far changes will not affect the magnification of the imaging, widely used in the field of machine vision measurement and inspection.

Telecentric Mirror Features:

-

High image quality: the telecentric lens can provide high-resolution, low-distortion, perspective error-free images, which is suitable for high-precision and high-efficiency industrial vision inspection.

-

Strong adaptability: able to adapt to the shooting needs of different distances to meet a variety of industrial application scenarios.

-

High stability: It is not easy for focusing error to occur during long-term use, ensuring the stability of imaging.

Industrial lens imaging principles:

Industrial lenses are optical instruments based on the principles of optical physics and geometric optics, mainly used for inspection, imaging and measurement in industrial production. When light passes through a lens, it will be refracted and focused according to the shape and size of the lens, the angle of incidence, the angle of refraction, etc., and eventually form an image of the object on the imaging surface (e.g., CCD camera device, film, etc.).

Industrial Lens Features:

-

Versatility: There is a wide range of industrial lenses, including fixed-focus lenses, zoom lenses, wide-angle lenses, etc., which are suitable for different industrial application scenarios.

-

Imaging quality: Although ordinary industrial lenses can also provide clear images, their resolution and distortion control may not be as precise as telecentric lenses, especially in the field of high-precision measurement and inspection. -

Stability: Some industrial lenses, such as fixed focal length lenses, are more stable due to their fixed focal lengths, making them suitable for application scenarios that require higher stability.

Telecentric lens application scenarios:

-

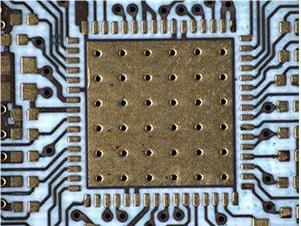

High-precision measurement: such as tiny component inspection on circuit boards, textile fiber inspection, etc., which requires high-resolution and low-distortion images.

-

Machine vision inspection: In automated production lines, telecentric lenses can ensure consistent imaging of objects at different positions and distances, improving inspection accuracy and efficiency. -

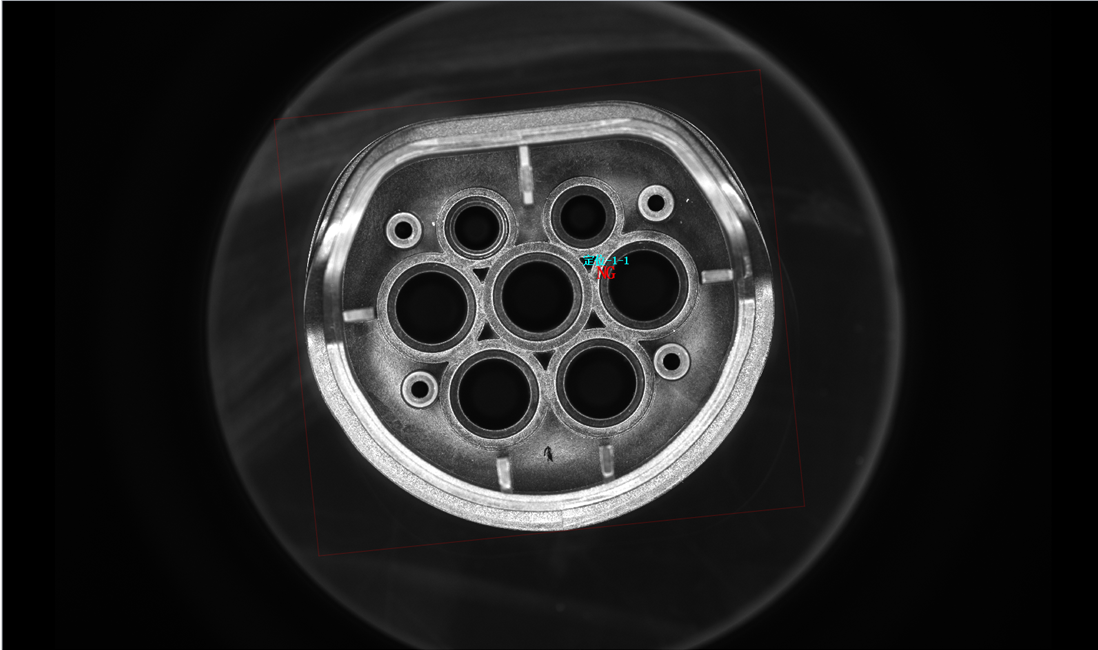

Three-dimensional object inspection: For objects with apertures and three-dimensional objects, telecentric lenses can provide more accurate imaging.

Industrial lens application scenarios:

-

Production line monitoring: Used for parts identification and positioning on production lines, object contour detection, etc. There are certain requirements for imaging quality, but they do not necessarily need to reach the precision of telecentric lenses.

-

Wide applicability: Due to the versatility and relatively low cost of industrial lenses, they are widely used in a variety of industrial scenarios, such as security monitoring and quality inspection.

Telecentric lenses and industrial lenses differ in imaging principles, characteristics and practical application scenarios. Telecentric lenses have unique advantages in the field of machine vision inspection and high-precision measurement due to their high precision, low distortion and no perspective error; while industrial lenses play an important role in a wide range of industrial application scenarios due to their versatility and cost-effectiveness.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com