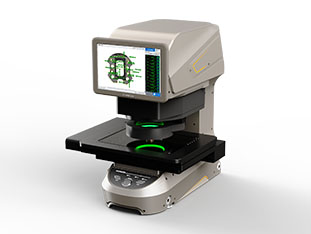

Measurement Systems|Flash Meter in Sewing Machine Hardware Measurement Applications

With the increasing demand for product quality and precision in the manufacturing industry, the accuracy and efficiency of dimensional measurement of sewing machine fittings, as a key component, has become an important part of the production process. In view of the small size and irregular shape of sewing machine fittings, and the high requirements for measurement accuracy, the POMEAS Flash Meter, with its unique technical advantages, has become the ideal choice for solving this problem.

Measurement requirements and difficulty:

- Small size and irregular shape:sewing machine hardware parts are often small in size and complex in shape, such as gears, screws, bearings, etc., which poses a challenge for traditional measuring tools.

- High precision:the measurement accuracy needs to reach 1um, which puts high demands on the precision and stability of the measurement equipment.

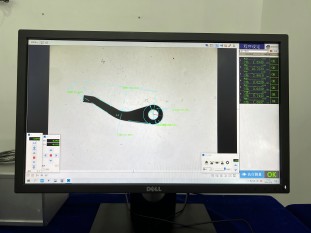

- Multi-dimensional measurement:the need to simultaneously measure the roundness, length, width and other dimensional parameters of the product, requiring the measurement system has a comprehensive measurement capability.

Advantages of the POMEAS flash meter:

One-button measurement, efficient and quick: POMEAS flash tester adopts advanced image recognition and processing technology, users only need to set up a simple, one-button can start the measurement program, greatly improving the measurement efficiency. For mass production of sewing machine hardware, the flash tester can realize fast and continuous measurement, effectively saving working hours and improving production efficiency.

High-precision measurement to meet stringent requirements: The POMEAS flash tester is equipped with high-precision measurement capability, which can easily meet and exceed the 1um measurement accuracy requirement. Its high-resolution camera and precision optical system ensure the accuracy and reliability of measurement results.

Strong adaptability to deal with complex shapes: For the irregular shape of sewing machine hardware parts, the POMEAS flash tester is able to automatically identify and measure a variety of complex shapes through flexible programming and customized measurement solutions, ensuring the comprehensiveness and accuracy of the measurement results.

Easy to Operate, Reduced Learning Costs: The Flash Meter's user interface is simple and intuitive, allowing even novice users to master its operation in a short period of time. In addition, POMEAS provides comprehensive technical support and training services to help users quickly get started and make full use of the equipment's functions.

Strong data processing and analysis capabilities: In addition to the basic measurement functions, the POMEAS flash meter also has powerful data processing and analysis capabilities. Users can export measurement data for further analysis and comparison, providing strong support for continuous improvement of product quality.

Measurements:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com