In the production process of cell phones, the precision control of screen size is a key link to ensure product quality and subsequent assembly efficiency. Since the precision of cell phone screen size is required to reach the micron level, it is particularly important to adopt high-precision and high-efficiency inspection equipment. As an advanced measuring tool, the in-line image measuring instrument has become an indispensable equipment for cell phone screen size inspection.

1. Equipment characteristics

-

High Precision Measurement:Able to meet micron-level measurement accuracy requirements to ensure the accuracy of measurement results。

-

High Efficiency :Automated operation, without manual intervention, can quickly complete a large number of samples testing。

-

Non-contact Measurement:Will not cause any damage to the phone screen, ensuring the integrity of the product。

-

Easy to integrate:Easily integrated into existing production lines for seamless integration。

2. Measurement process

-

Sample Transfer:The cell phone screen automatically enters the measurement area via a conveyor belt.

-

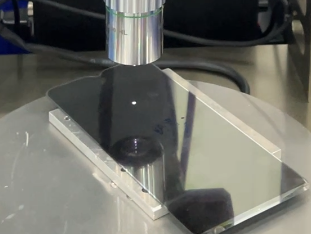

Image Acquisition:A high-definition camera captures images from the cell phone screen and transmits them to the measurement system.

-

Image Processing:The system preprocesses the image and extracts key features such as edges and corner points.

-

Size Measurement:Based on the extracted features, the system utilizes a sophisticated measurement algorithm to calculate the screen size.

-

Result Output:Measurement results are shown in real time on the display and data can be exported as required.

3. Data processing and feedback

-

Data Analysis:The system can statistically analyze measurement data to identify potential quality problems.

-

Judgment of Results:According to the preset tolerance range, the system automatically judges whether the screen size is qualified or not, and marks the product OK/NG.

-

Real-time Feedback:Real-time feedback of measurement and judgment results to production personnel for timely adjustment of production parameters or product sorting.

Program Advantages

1. Increased productivity

The automated operation of on-line image measuring instrument greatly reduces the manual intervention and improves the inspection speed, thus increasing the production efficiency.

2. Ensure product quality

High-precision measurement and strict tolerance control ensure the stability and consistency of product quality.

3. Reduce production costs

By reducing manual inspection and lowering the scrap rate, it reduces production costs and improves the economic efficiency of the enterprise.

4. Real-time quality monitoring

The system can provide real-time feedback on the measurement results and judgment results to help production staff find and solve problems in a timely manner, ensuring the stability and controllability of the production process.

As a kind of high-precision and high-efficiency testing equipment, online image measuring instrument plays an important role in cell phone screen size testing. It can quickly and accurately measure the size of the cell phone screen and provide real-time feedback on the measurement results and judgment results, which provides great convenience for production personnel.

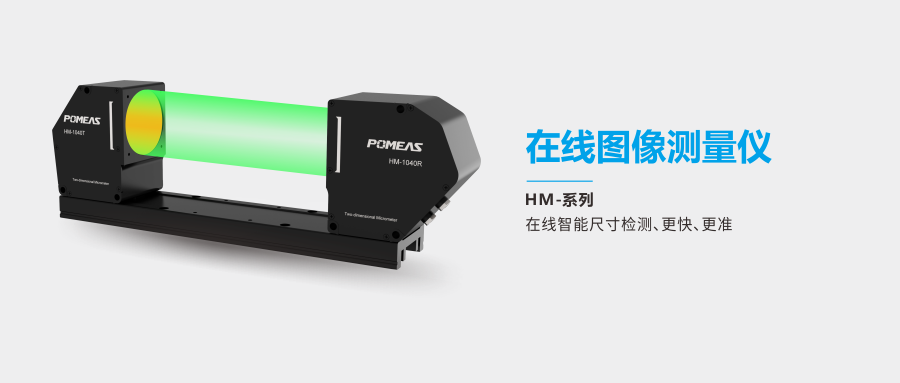

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com