Application Examples of Image Dimensional Gauge in CNC Tool Inspection

CNC tools are indispensable tools for computer numerical control (CNC) machine tools for metal cutting processing. They are widely used in the machining of various materials, including metals, plastics, wood, etc. They are used in a wide range of applications involving aerospace, automotive manufacturing, mold processing, precision instruments, etc. The performance and accuracy of CNC tools directly affects the quality of the processed parts, productivity, and manufacturing costs, and therefore, it is particularly important to conduct accurate and rapid inspection of CNC tools in industrial production.

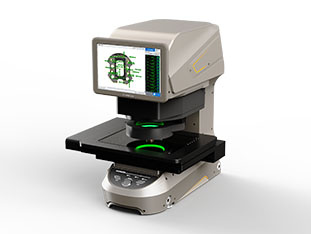

The POMEAS Image Gauge is a highly accurate and efficient measuring device designed for CNC tool inspection. It has a number of high-end features that ensure fast and accurate measurement of CNC tool profile dimensions.

Double Dual Side Telecentric Lens: This lens provides a wider field of view and higher measurement accuracy, ensuring complete capture and accurate measurement of CNC tool contours.

Twenty-million-pixel high-definition industrial camera: High-definition pixels and powerful image processing capabilities enable the image measuring instrument to capture finer image details, further improving measurement accuracy.

Three types of light source configurations: including a white ring light source, a parallel bottom light source, and a coaxial light source, these light sources can be optimally selected according to different tool materials and surface characteristics, ensuring image clarity and contrast, and improving measurement accuracy.

Altimetric spectral sensor: This sensor enables precise measurement of tool height, further enriching the dimensions of the measurement data and improving the comprehensiveness and accuracy of the measurement.

Detection Advantage:

1, rapidity: the use of advanced image processing technology and high-performance hardware configurations, PMIS image measuring instrument can complete a large number of tool measurement tasks in a short period of time, greatly improving the inspection efficiency.

2, accuracy: through the high-precision lens, camera and light source configuration, as well as advanced measurement algorithms, PMIS image measuring instrument can realize the accurate measurement of CNC tool profile size, to meet the needs of high-precision machining.

3、Comprehensive: POMEAS image measuring instrument can not only measure the contour size of the tool, but also the surface quality of the tool, hardness and other properties of the inspection, to provide comprehensive inspection data.

4、Ease of use: The user interface of POMEAS image measuring instrument is friendly and easy to operate, users only need to operate according to the software prompts to complete the measurement task, no need for professional measurement skills.

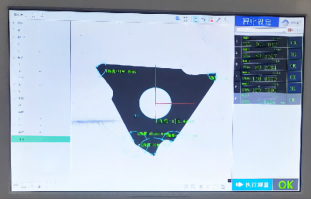

Test results:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com