360° lens in the detection of defects in the inner wall of the metal

Inspection of metal interior walls has always been a challenging task, especially when the surface of the interior wall is smooth and reflective, and it is often difficult to obtain clear and accurate inspection images with conventional inspection methods. Defects on the inner wall, such as scratches, dents, corrosion, etc., not only affect the quality of metal products, but also may pose a potential threat to the safety of use. Therefore, it is crucial to develop an efficient and accurate solution for detecting defects on the inner wall of metals.

Detecting Targets:

1、Internal Wall Defect Detection: Identify and record various defects on the inner wall of the metal, such as scratches, dents and corrosion.

2、Scratch detection: Identify and quantify scratches on the inner wall and assess their impact on product performance.

3、Smoothness Assessment: Assess the smoothness of the inner wall to ensure that the product meets the predetermined quality standards.

Detection Program:

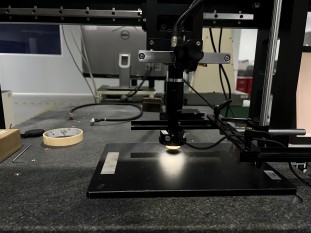

360° Inner Wall Lens: The POMEAS 360° inner wall lens is used to capture a full view of the metal inner wall without any dead angle. This lens design overcomes the challenges posed by smooth and reflective interior walls, ensuring that a clear and complete image of the interior wall is obtained.

Ring Light Source: Used in conjunction with a ring light source, this provides uniform illumination of the interior wall, eliminating shadows and reflections. This light source design allows the inner wall to be fully detailed, providing favorable conditions for defect detection.

High Definition Industrial Camera: Capturing images of the inner wall with a high definition industrial camera ensures clarity and resolution of the image. The high stability and reliability of the industrial camera can meet the needs of long time and high intensity inspection.

Test Results Display:

Detection Program Advantage:

Full coverage without dead ends: The 360° interior wall lens provides a full view of the metal interior without dead ends, ensuring that every corner is detected.

High clarity: The combination of a ring light source and a high-definition industrial camera greatly improves the clarity of the image of the inner wall, and the details of defects can be fully displayed.

High inspection efficiency: the inspection program can complete a large number of metal wall inspection tasks in a short period of time to improve production efficiency.

Strong scalability: the inspection solution can be customized and optimized according to the actual needs to meet the inspection needs of different metal products.

The inspection solution using a combination of POMEAS 360° inner wall lens, ring light source and HD industrial camera can realize the efficient and accurate detection of defects on the inner wall of metal. This inspection solution not only improves the quality and safety of metal products, but also reduces the production cost and time cost, which has important application value and development prospect.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com