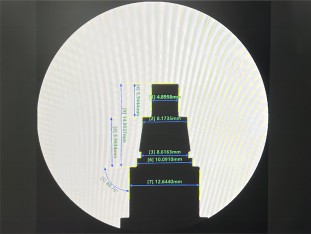

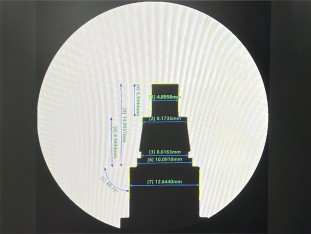

Example of Die Casting Measurement by On-line Image Measuring Instrument

The importance of die castings in industrial manufacturing cannot be ignored, and they are widely used in many key areas such as automotive, electronics and machinery. Given that die castings often have complex geometries and extremely high dimensional accuracy requirements, their measurement is particularly important and challenging.

Challenges of Die Casting Measurement

The complex shapes and fine dimensions of die castings, such as length, width, distance, curvature, aperture, thickness, etc., require measuring tools with a high degree of accuracy and adaptability. However, the unevenness and concavity problems that may exist on the surface of die castings, as well as the poor structure of the castings, often bring many difficulties to the traditional measurement methods. In addition, the casting in the manufacturing process may produce deformation, more make the measurement work becomes complex and challenging.

POMEAS breakthrough in online image measurement

To overcome these challenges, the POMEAS In-Line Image Gauge revolutionizes die casting measurement with its advanced image processing technology and high accuracy measurement algorithms. The gauge is designed with a high depth-of-field telecentric system that ensures accurate measurements no matter how much the part shifts in the depth-of-field range. The near distortion-free design and full field of view face-finishing technology ensures that the entire field of view area is measured with extremely high accuracy.

Practical application process

Measuring die castings is easy and efficient in practice with the POMEAS In-Line Image Gauge. Simply place the die casting on the table of the meter and adjust the light source to obtain a clear image. Afterwards, the measurement is programmed to be automatic and can be started simply by placing the product. Once the tolerance data is entered, the gauge automatically determines whether the dimensions are acceptable or not, and a detailed measurement report is exported at the touch of a button, making it extremely convenient for users to analyze and process the results.

The POMEAS in-line image measuring instrument demonstrates the following significant advantages in die casting measurement:

Fast and efficient: just simply place the product, the measuring instrument can automatically complete the measurement task, which greatly improves the working efficiency.

Accurate and reliable: High depth of field telecentric system design and distortion-free technology ensure high accuracy and reliability of measurement.

Intelligent and flexible: Equipped with a variety of measuring tools, it is suitable for the measurement needs of different industries and products.

Versatility: In addition to basic size measurement, it can also realize a variety of on-line inspection functions, such as geometric tolerance measurement, standard contour comparison and defect distance measurement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com