Application of in-line image measuring instrument in metal gear measurement

As an important transmission element in mechanical equipment, the accuracy and performance of metal gears directly affect the operational efficiency of the entire mechanical system. However, the measurement of metal gears has always been a major challenge for the industry. Due to their uneven and bumpy appearance and small tooth convexity, it is often difficult to ensure the accuracy and efficiency of measurement by traditional measurement methods. At this point, the in-line image measuring instrument, with its unique advantages, provides a new solution for the measurement of metal gears.

Detection Program:

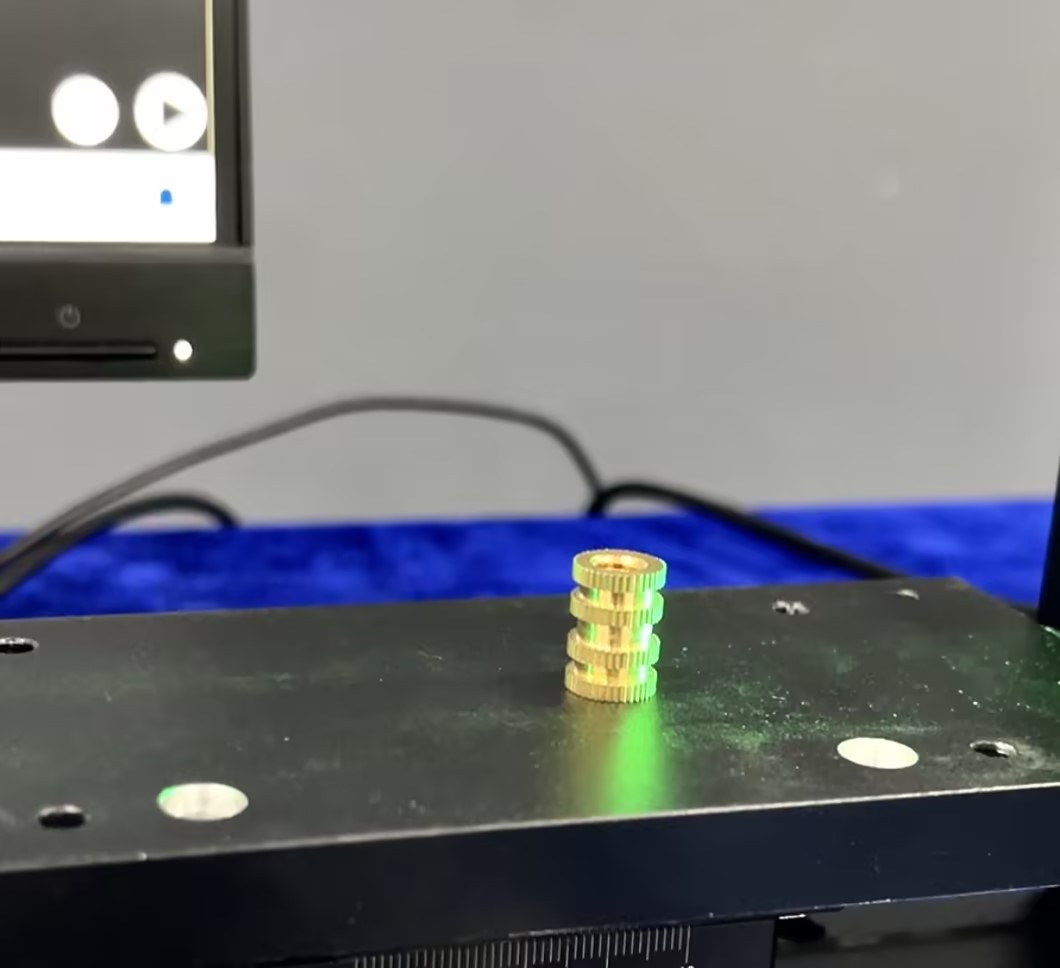

By placing the metal gear on the measuring platform, the in-line image measuring instrument instantly recognizes the product and reads the data presented on the system, saving inspection time.

Test Results:

Online image measuring instrument can quickly and accurately obtain the parameters of gears through high-resolution camera and image processing technology. Its advantages in metal gear measurement are mainly reflected in the following aspects:

1, rapidity: online image measuring instrument only needs to place the gear on the measurement platform, through the automatic identification and localization function, you can quickly obtain the various parameters of the gear. Compared with the traditional measurement method, it greatly shortens the measurement time and improves the measurement efficiency.

2, high precision: online image measuring instrument using high-resolution measuring head and advanced image processing algorithms, can accurately capture the tiny features of the gear, to achieve high-precision measurement. At the same time, the instrument is also equipped with automatic calibration and compensation functions, further improving the measurement accuracy.

3、Intelligent: The online image measuring instrument is equipped with intelligent identification and analysis functions, which can automatically identify the gear tooth shape, tooth pitch, tooth height and other parameters, and analyze the data. In addition, the instrument also supports data export and report generation function, which is convenient for users to manage and analyze data.

Online image measuring instrument has been widely used in the field of metal gear measurement with its advantages of fast, accurate and intelligent measurement. It not only solves the problems faced by traditional measurement methods, but also improves the measurement efficiency and accuracy, providing strong support for the manufacturing and quality control of mechanical equipment.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION