Measuring principle:

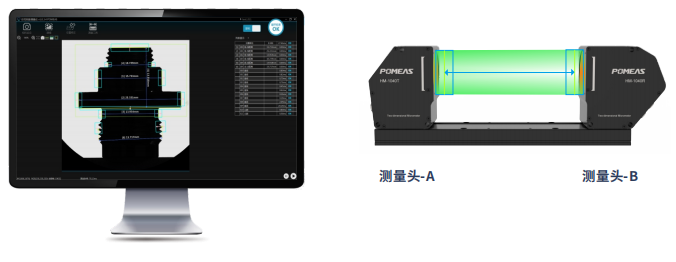

Online image measuring instrument is an advanced measuring tool based on computer vision technology. Its principle mainly relies on a high-precision camera, image processing software and advanced algorithms to realize fast, non-contact measurement of object size, shape, contour and other parameters.

During the measurement process, the image of the object to be measured is first captured by a high-precision camera. This step is crucial as it directly determines the precision and accuracy of the subsequent measurement. The camera transmits the captured image to an image processing software, which performs a series of processing on the image, such as denoising, enhancement, edge detection, etc., in order to extract the key features of the object.

Next, the processed image is analyzed and computed by specific algorithms. These algorithms usually include image matching, feature recognition, 3D reconstruction, etc., and are able to accurately determine parameters such as the size, shape and contour of the object. At the same time, these algorithms are able to correct and optimize the measurement results to further improve the accuracy and reliability of the measurement.

With its high accuracy measurement, on-line real-time fast measurement, and support for multiple product measurement, the HM series of POMEAS in-line image measuring instruments provides an efficient and accurate measurement solution for modern manufacturing industries.

High Precision Measurement: The on-line image measuring instrument of POMEAS adopts high resolution image sensor and advanced image processing algorithm, which is able to realize extremely high measurement precision. Its accuracy can reach 1um, which can meet all kinds of high-precision measurement requirements. This high precision measurement not only ensures the accuracy of measurement results, but also provides reliable data support for subsequent product quality control and process improvement.

On-line real-time fast measurement: POMEAS on-line image measuring instrument is characterized by on-line real-time fast measurement. Users only need to place the product to be measured on the measurement platform, and the device can automatically capture the image and process it to quickly output the measurement results. This fast measurement method greatly improves production efficiency, shortens the production cycle, and reduces human error.

Supports multiple product measurements: With its multi-industry versatility, POMEAS in-line image measuring instrument can support a wide range of different types and specifications of product measurements. Whether it is products from hardware, plastics, rubber and other industrial manufacturing fields, or products from other industries such as medical and electronics, they can all be measured efficiently and accurately by this equipment. This multi-industry versatility makes PEMS In-Line Image Measuring Instruments have a wide range of applications and market demand.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com