Comparison of advantages and disadvantages of laser autofocus microscopy systems

Laser autofocus microscopy systems are widely used in the semiconductor wafer, green energy, and photovoltaic industries because of their unique advantages. However, like any technology, it has its inherent advantages and disadvantages. This paper will provide a detailed comparison of the advantages and disadvantages of laser autofocus microscopy systems.

Pros:

-

High Precision Inspection:The laser autofocus microscope can provide micron and even nanometer-level inspection accuracy, which makes it extremely valuable for applications in semiconductor manufacturing, materials science, and other fields. It is capable of accurately identifying and analyzing information such as the microscopic morphology, composition and structure of samples.

-

Rapid testing:The system has a fast autofocus function that enables it to accomplish the task of inspecting a large number of samples in a short period of time. This feature makes it particularly useful in high-throughput inspection scenarios such as quality control of semiconductor wafers and screening of photovoltaic materials.

-

Non-contact detection:Compared to traditional contact inspection tools, laser autofocus microscopy systems utilize non-contact inspection, avoiding the possible introduction of contamination and damage, and ensuring the integrity and safety of the sample.

-

Visualization of test results:Inspection results can be displayed as images or videos, making the inspection process more intuitive and easier to understand. This enables faster and more accurate identification and problem solving for researchers and technicians.

-

Highly adaptable:The system can be flexibly adjusted to different samples and testing needs, adapting to many types of samples and testing scenarios.

Drawbacks:

-

Costs are high:Equipment for laser autofocus microscopy systems is typically more expensive, and for some laboratories or small businesses with limited budgets, the cost of purchase and maintenance may be an important consideration.

-

Technical complexity:The technical complexity of the system is high due to the integrated laser technology and autofocus function. This requires a certain level of specialized knowledge and skills on the part of the operator in order to ensure the proper functioning and efficient use of the system.

-

Requirements for the operating environment:Laser autofocus microscopy systems have certain requirements for the environment in which they are used, such as temperature, humidity, and vibration. This may require additional equipment or measures to keep the environment stable to ensure the accuracy and reliability of the system.

-

Possible limitations:Despite the adaptability of the system, there may be limitations for some specific types of samples or detection needs. For example, for some fluorescently stained samples, additional processing or labeling steps may be required for effective observation.

-

Maintenance and upkeep:Laser autofocus microscopes require regular maintenance and servicing to ensure their performance and stability. This may require specialized technicians to operate and may involve additional cost and time investment.

Laser autofocus microscopy systems are widely used in a variety of industries for their high accuracy, fast detection and non-contact inspection. However, their high cost, technical complexity and environmental requirements are some of the drawbacks that need to be taken into consideration when using them.

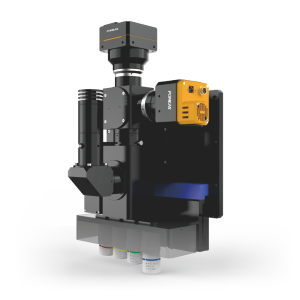

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com