An article to take you to understand the industrial lens parameter table

Industrial lenses are an integral part of industrial vision systems. However, for beginners, the various terms on the lens parameter list can be confusing. This article will help you understand these parameters so that you can better select and use industrial lenses.

1. Resolution

Resolution is the smallest size of detail that a lens can capture. It is usually measured in pixels per millimeter (LP/mm) or the number of pixels. The resolution of a lens should at least match the resolution of the camera's sensor to fully utilize the camera's performance.

2. Focal Length

The focal length determines the relationship between the distance between the lens and the subject and the size of the image. The longer the focal length, the farther the distance between the lens and the object, but the imaging size will be larger. Fixed-focus lenses have a fixed focal length, while zoom lenses can be adjusted within a certain range.

3. Aperture range

The aperture is the device that controls the amount of light entering the lens. The aperture range indicates the maximum and minimum size at which the aperture can be opened. Larger apertures (smaller aperture values) allow more light to enter and are suitable for low-light environments, but may result in a shallower depth of field.

4. Maximum Sensor Size

The maximum Sensor size is the largest image sensor size that the lens can support. When selecting a lens, make sure that the maximum Sensor size of the lens is greater than or equal to the sensor size of the camera.

5. Field of View (FOV)

Field of View is the range of horizontal or vertical angles that a lens can see. It depends on the focal length and sensor size. A larger FOV means the lens can capture a wider area.

6. Imaging range

Imaging range is the range of object distances that can be clearly imaged by a lens at a given working distance. This is usually related to the depth of field of the lens.

7. Image size

Imaging size is the actual size of the image formed by an object on the sensor. It depends on the focal length, working distance and sensor size.

8. Focus and aperture adjustment

Most industrial lenses allow the user to adjust the focus and aperture manually or automatically. The focus adjustment is used to ensure a sharp image, while the aperture adjustment is used to control the amount of incoming light.

9. Aberration

Aberration is the geometric distortion that occurs when a lens is imaged. Aberration rate indicates the degree of this distortion. When selecting a lens, the effect of aberration on image quality should be considered.

10. Back Focal Length (BFL)

The back focal length is the distance from the last optical surface of the lens to the image sensor. Understanding the back focal length is important to ensure that the lens is correctly fitted and mounted to the camera.

11. Filter Size

Filter size indicates the maximum diameter of the filter that can be mounted on the front of the lens. This allows the user to add different types of filters such as polarizing filters or ND filters as needed.

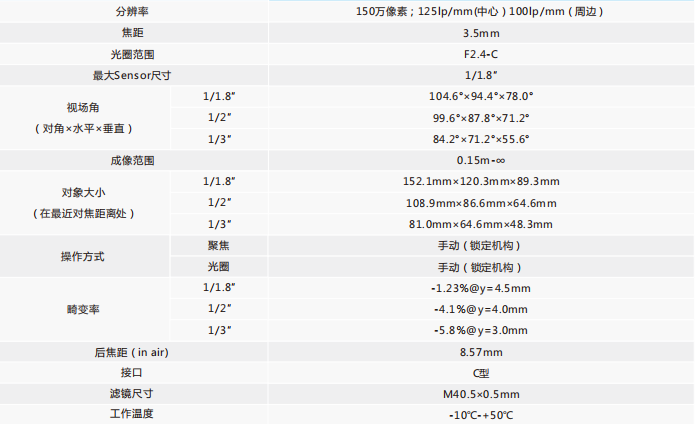

Parameters of POMEAS Industrial Lens

Understanding these parameters is key to choosing the right industrial lens, and can also help you better understand how industrial vision systems work and the importance of the lens in the overall system. When you grasp the meaning of these parameters and how they affect image quality, you will be able to more accurately evaluate the performance of different lenses and select the one that best suits your application needs.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com