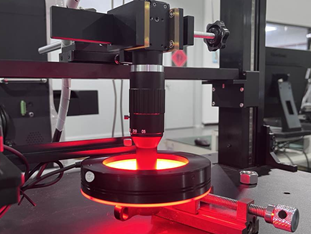

Aiming at the difficulty of detecting dirty and defective bores, we propose an inspection scheme based on a 500w industrial lens, ring and coaxial light sources, and a high-performance industrial camera. The solution is characterized by high efficiency, accuracy, flexibility and scalability, which can effectively solve the problems of traditional inspection methods and improve the efficiency and accuracy of bore inspection. The application of industrial lenses in the field of bore inspection has significant advantages, bringing unprecedented convenience and efficiency improvement to many industries.

Omni-directional testing:Traditional bore inspection methods usually require multiple rotations of the workpiece or the use of multiple tools to complete a comprehensive inspection. The use of industrial lenses, especially 360° bore inspection lenses, can complete the inspection of the entire bore at an angle, without the need to frequently adjust the position of the workpiece, greatly improving the inspection efficiency and accuracy.

High-resolution imaging:Industrial lenses are made of high-quality optical materials and precision manufacturing process, which can provide clear, high-resolution imaging quality. This enables all kinds of defects, foreign objects and details in the bore to be clearly displayed, which helps to find and solve problems in time and ensure the quality of products.

Highly adaptable:Industrial lenses can be used with various types of inspection equipment to adapt to different inspection scenarios. Whether it's aerospace, power production, automotive manufacturing or any other industry, you can find the right industrial lens for your bore inspection needs.

Flexibility and accessibility:Industrial lenses are usually compact and lightweight, easy to carry and simple to operate. This allows them to be used in a variety of environments, whether it's a small space or a complex field environment.

Advanced image control features:Some advanced industrial lenses are also equipped with clear imaging technology based on CCD image sensors and a variety of advanced image control features, such as dark enhancement, adaptive noise reduction ANR, distortion correction, and color saturation adjustment. These features make inspection images clearer and more accurate, helping to find more details and potential problems.

Intelligent assistive functions:Some industrial lenses also have intelligent auxiliary functions, such as ADR artificial intelligence-assisted defect judgment function and blade intelligent counting analysis function. These functions can automatically identify and record defects, analyze the number of blade grades, etc., reducing the repetitive labor of borehole inspectors and improving inspection efficiency and accuracy.

Measurement functions:The measurement capabilities of industrial borescopes are particularly important in aerospace borehole exploration. Through the use of industrial lenses, the size and location of defects can be accurately measured, providing the data necessary to support the assessment of the impact of defects on the engine.

The application of industrial lenses in the field of borehole inspection has significant advantages, which not only improves the inspection efficiency and accuracy, but also reduces the cost and time consumption. With the continuous progress and innovation of technology, I believe that industrial lenses will play a more important role in the future.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com