In the design and production of smartphones, quality inspection of the phone casing is an important part of ensuring product quality and user experience. With its advanced 3D Structured Light Measurement technology, POMEAS brings a revolutionary solution for quality inspection of cell phone housings.

Introduction to 3D structured light measurement technology:

POMEAS 3D Structured Light Measurement Technology is a non-contact measurement method based on optical principle, which projects a specific structured light pattern onto the surface of the object to be measured, and utilizes a camera to capture the changes of the reflected light, thus obtaining the 3D geometric information of the surface of the object. This technique has the advantages of high accuracy, high efficiency and non-contact, and is especially suitable for the measurement of complex surfaces and fine structures.

POMEAS 3D Structured Light Measurement Technology for Mobile Phone Housing Inspection:

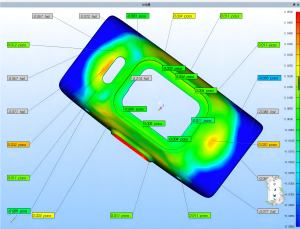

Flatness and Contour Measurement: As the external protective structure of a cell phone, the flatness and contour of a cell phone case have a significant impact on the appearance and performance of the phone. POMEAS 3D structured light measurement technology can quickly and accurately obtain the flatness and contour data of the cell phone case and compare it with the standard documents to ensure that the product quality meets the design requirements.

Dimensional Measurement: The dimensional accuracy of the phone casing has a significant impact on the assembly and performance of the phone. POMEAS 3D structured light measurement technology can realize accurate measurement of the length, width, height, radius, R angle and other dimensions of the cell phone shell to ensure the consistency and stability of the product dimensions.

Surface Defect Detection: The surface quality of a cell phone case directly affects the user's experience. POMEAS 3D structured light measurement technology can detect scratches, notches, indentations, bump marks, foreign objects and other defects on the surface of cell phone shells, so that they can be detected and dealt with in a timely manner to improve product quality.

Advantages of POMEAS 3D structured light measurement technology:

1、High precision: The 3D structured light measurement technology of POMEAS has very high measurement precision, which can meet the high precision requirements of cell phone shell quality inspection.

2, high efficiency: the technology can quickly complete the cell phone shell of the three-dimensional data acquisition and measurement and analysis, improve inspection efficiency, reduce production costs.

3, non-contact measurement: POMEAS 3D structured light measurement technology adopts non-contact measurement method, avoiding the wear and tear and errors that may arise from traditional contact measurement.

4, wide adaptability: the technology is applicable to a variety of materials, colors and shapes of cell phone shells, with strong versatility and adaptability.

POMEAS 3D structured light measurement technology brings a revolutionary solution for quality inspection of cell phone housings. Through high-precision, high-efficiency, non-contact measurement, the technology can realize comprehensive inspection of flatness, contour, size and surface defects of cell phone housings to ensure product quality meets the design requirements. At the same time, the technology has a wide range of adaptability, can be applied to a variety of materials, colors and shapes of cell phone shell inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com