Industrial lens of the simulation of industrial vibration plate vision program

In modern industrial production lines, industrial vibrating trays are widely used in electronics, hardware, toys, food and other industries as a kind of efficient material conveying and sequencing equipment. However, with the improvement of product precision and the acceleration of production speed, the accuracy and stability requirements of vibrating tray material conveying and sequencing are getting higher and higher. Therefore, we propose an analog industrial vibrating tray vision solution based on industrial lenses, aiming at real-time monitoring and precise control of vibrating tray material conveying and sequencing by means of a high-precision vision system.

Detection Program:

Hardware device selection software algorithm design

1、Industrial Lens: Choose an industrial lens with high resolution, low distortion and large field of view to ensure that it can clearly capture images of materials on the vibration plate.

2、Industrial camera: according to the actual need to choose the appropriate frame rate, resolution and interface type of industrial camera, to achieve seamless connection with the industrial lens.

3、Light source: according to the characteristics of the material and the vibrating plate working environment, select the appropriate type of light source and installation to ensure stable and reliable image quality.

Software Algorithm Design System Integration and Debugging

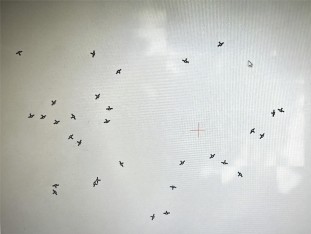

1、Image pre-processing: Perform pre-processing operations such as filtering and enhancement on the captured image to improve the image quality.

2、Target detection and localization: use image processing algorithms to identify and locate the material and extract the characteristic information of the material.

3、Trajectory analysis and prediction: Predict the future position and movement state of the material according to its movement trajectory and speed information.

4、Control strategy design: according to the prediction results and actual needs, design appropriate control strategies to realize accurate control of vibrating plate material conveying and sorting.

System Integration and Commissioning

- Integrate the hardware devices with the image processing system to build a complete vision system.

- Debug and optimize the vision system to ensure stable and reliable system performance.

- Fine-tune the control strategy according to the actual production requirements to realize the best control effect.

Program Strengths:

High precision: adopting high-resolution industrial lenses and cameras, it can realize high-precision identification and positioning of materials.

Real-time: adopting high-performance image processing hardware and software to realize real-time processing and analysis of image data.

Flexibility: The control strategy can be fine-tuned according to the actual production requirements, adapting to different materials and the working environment of the vibration plate.

Visualization: Through the intuitive image interface to display the material's movement status and position information, it is convenient for operators to monitor and adjust in real time.

In the era of continuous improvement of industrial automation level and rapid development of intelligent manufacturing, the industrial lens of the analog industrial vibration plate vision program can not only be used to improve the accuracy and stability of the vibration plate material conveying and sorting, but also can be applied to other industrial automation fields that require high-precision visual inspection and control.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com