With the rapid development of modern electronics manufacturing industry, the PCB (printed circuit board) board inspection accuracy and efficiency requirements are increasing. Traditional PCB board inspection methods have been difficult to meet the demand for high precision and high efficiency. Against this background, POMEAS five million FA lens inspection solution has demonstrated its strong advantages in the field of PCB inspection by virtue of its high-resolution and high-definition features.

PCB board products are widely used in communication, computer, consumer electronics and other fields. Due to the wide variety of products and complex PCB board design, the precision and efficiency of the inspection equipment is highly required. In order to improve the product quality and reduce the defective rate, POMEAS has developed a 5 million FA lens vision inspection program for PCB board inspection.

Detection Program:

Lens: Adopt five megapixel lens to ensure that the captured image of the PCB board is high in clarity and rich in details, which can meet the requirements for the detection of minor defects.

Camera: Selection of high-definition industrial cameras with high resolution, high frame rate, low noise and other characteristics, to capture the dynamic image of the PCB board in real time, to ensure that the detection of real-time and accuracy.

Light source: the choice of ring light source is crucial for PCB board detection. According to the PCB board material, color, reflection characteristics and other factors, select the appropriate type of light source and angle to ensure that the captured image brightness uniformity, high contrast, to facilitate subsequent image processing and analysis.

Image software: image software is the core of the PCB board inspection system, which is responsible for processing and analyzing the images captured by the camera to identify defects on the PCB board.

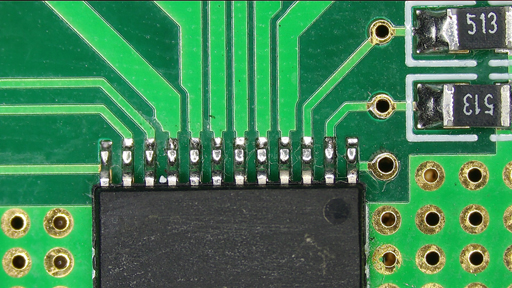

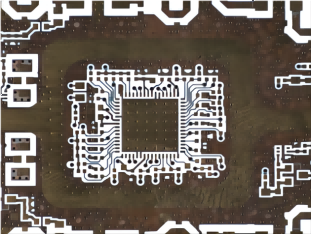

Test results:

Detecting the effects of application:

1, the detection accuracy is improved: five million FA lens of high resolution, high definition characteristics, so that the PCB board on the tiny defects can also be accurately identified, thus improving the accuracy of detection.

2, improved detection efficiency: automated inspection equipment can quickly complete the PCB board shooting, processing and analysis process, greatly improving the efficiency of detection. At the same time, it reduces the possibility of manual intervention and misjudgment.

3, product quality improvement: through the introduction of five million FA lens for PCB board inspection, the enterprise effectively reduced the rate of defective products, improve product quality and customer satisfaction.

POMEAS five million FA lens inspection has shown strong advantages in the field of PCB board inspection. Through specific application cases, it can be seen that the five million FA lenses can improve the accuracy and efficiency of the inspection, reduce the defective rate and improve product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com