The simplified process of measuring cylinders with a fully automated image measuring machine (flash probe) is very efficient indeed and can be done in just three steps. Below is a detailed explanation of these three steps:

I: Place the cylinder

Place the cylinder to be measured on the worktable of the automatic image measuring instrument (flash measuring instrument) to ensure that the cylinder is stable and in the correct position. This step is the foundation of the measurement, the correct placement can ensure the accuracy of the measurement results.

II: Click the button

After the cylinder is properly placed, click on the Start Measurement button through the operating interface of the fully automatic image measuring instrument (flash measuring instrument). At this point, the fully automatic image measuring instrument (flash measuring instrument) will start its internal camera and image processing system, the cylinder for high-precision image capture and processing.

During this process, the fully automatic image measuring instrument (flash measuring instrument) will automatically identify the cylinder edges, contours and other key features, and based on these features to carry out accurate size measurement and shape analysis.

III: Data Display

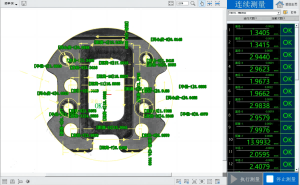

After the measurement is completed, the fully automatic image measuring instrument (flash measuring instrument) will display the measurement results in the form of numbers or graphics on the operating interface. These data usually include key parameters such as cylinder diameter, length, roundness, and information about possible surface defects.

Users can visualize these data and compare them with preset standard values to determine if the cylinder is qualified or requires further processing.

This simplified process makes full use of the automation and intelligence features of the image measuring instrument, making cylinder measurement faster, more accurate and more convenient. At the same time, it reduces the error of human operation and improves the reliability of measurement. In practice, this measurement method is widely used in a variety of industrial scenarios, providing strong support for quality control and product inspection in the production process.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION