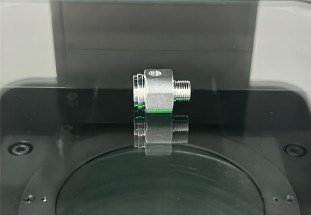

In the field of modern industrial manufacturing, cylinder measurement is a key aspect to ensure the performance and stability of mechanical equipment. Although the traditional measurement methods have a certain applicability, but in the batch measurement and efficiency is not satisfactory. However, with the continuous development of fully automatic image measuring instrument (flash meter), fully automatic image measuring instrument (flash meter), as an efficient and accurate measurement tool, is gradually becoming the most preferred choice for cylinder measurement.

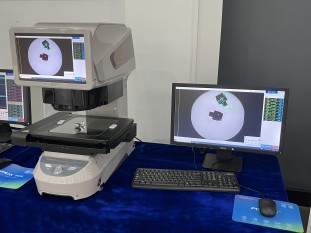

Fully automated image measuring instruments (flash measuring instruments) utilize high-resolution telecentric lenses and advanced image processing technology to quickly capture images of cylinders and accurately analyze and measure them. This non-contact measurement method not only avoids errors that may result from contact in traditional measurements, but also greatly improves measurement speed. What's more, the image measuring instrument is capable of realizing batch measurement of cylinders, which significantly improves the inspection efficiency.

In the batch measurement process, the fully automatic image measuring instrument (flash measuring instrument) can continuously measure multiple cylinders without manual intervention through the preset measurement program. Its high-speed computing capability and powerful data processing ability makes each cylinder measurement can be completed quickly, and timely output of the measurement results. This efficient measurement not only shortens the inspection cycle, but also reduces labor costs, bringing significant economic benefits to the enterprise.

In addition to high efficiency, the fully automatic image measuring instrument (flash measuring instrument) also has excellent performance in terms of measurement accuracy. Its high-resolution telecentric lens is able to capture the subtle features of the cylinder, while advanced image processing technology is able to accurately analyze and extract these features. This enables the fully automatic image measuring instrument (flash meter) to achieve very high accuracy when measuring parameters such as cylinder diameter, length and roundness. At the same time, its automatic calibration and compensation functions ensure the stability and reliability of the measurement results.

In addition, the fully automatic image measuring instrument (flash measuring instrument) has a wide range of applications. It can be used not only for cylinder measurement, but can also be applied to the measurement of other workpieces of various shapes and sizes. This flexibility allows the image measuring instrument to meet the measurement needs of different industries and different production lines, providing more choices and possibilities for companies.

With the advantages of high efficiency, precision, and batch measurement in cylinder measurement, POMEAS Image Measuring Instrument (Flash Measuring Instrument) provides a new inspection solution for enterprises.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com