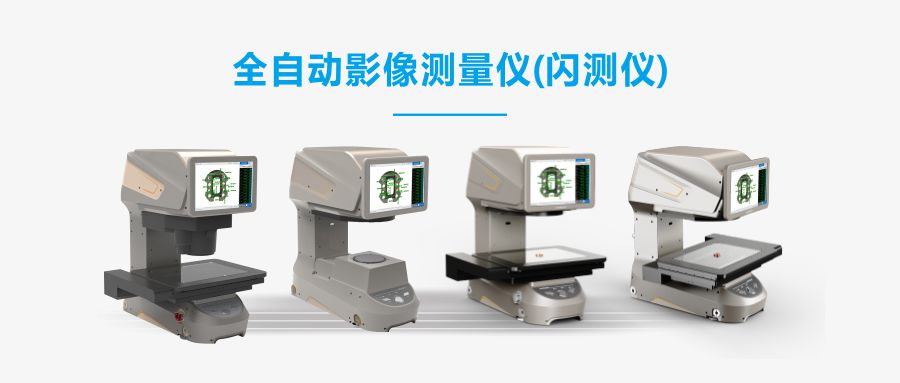

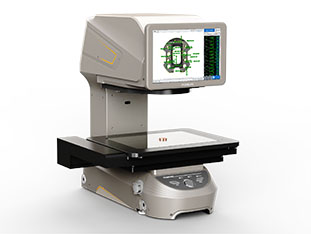

POMEAS Automatic Image Measuring Instrument (Flash Measuring Instrument) is a precision measuring instrument with new image measuring technology, featuring high resolution lens, 1% sub-pixel image processing and high precision algorithm analysis. It can realize one-button fast measurement through software calculation, and has the advantages of automatic detection, efficient measurement, automatic focusing, clear and intuitive data, and so on. POMEAS Automatic Image Measuring Instruments (Flash Measuring Instruments) are available in a wide range of models to meet the inspection needs of different customers.

Fully automatic image measuring instruments (flash measuring instruments) are particularly widely used in industrial manufacturing, and are able to improve the efficiency of production lines and the quality of products through the precise measurement of target objects. It is particularly suitable for high-volume measurement scenarios, and can realize one-button batch measurement of 2D plane dimensions, or be equipped with optical non-contact measuring heads to realize precise and rapid measurement of height dimensions, flatness and other parameters.

POMEAS fully automatic image measuring instruments (flash meters) are used in a number of industries in notable applications, such as:

1、Hardware industry: It is used to detect the size of screws, castings and other products such as threads, length, etc., to determine the tolerance automatically and judge whether it meets the production requirements.

2、Electronics industry: It is suitable for detecting the size of electronic components characterized by small, thin and soft, to ensure that the product size and tolerance are in line with the standard.

3、Automotive industry: it can be used to detect the precise size of automobile axle and fork and other parts, and realize fully automatic operation.

4、In addition, it is widely used in the fields of machinery, molds, injection molding, hardware, connectors, medical equipment, clocks and watches. For shafts, threads and other axisymmetric workpieces, the flash tester can be used for batch online measurement.

Inspection with a POMEAS automatic image measuring machine (flash meter) not only improves product quality and reliability, but also reduces production costs and improves production efficiency. Due to its efficient inspection capability, it can shorten the production cycle, detect product abnormalities and deal with defects in a timely manner, avoid mass production of unqualified products, and reduce waste and repeated processing. Meanwhile, with the development of Industry 4.0 and smart manufacturing, the automated inspection capability of the flash measuring instrument makes the automation level of the whole production process improved.

With its high precision, high efficiency and wide applicability, POMEAS fully automated image measuring instruments (flash measuring instruments) play an important role in many industries, helping to improve the competitiveness of enterprises and realize more efficient, accurate and reliable production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com