Differential interference DIC inspection of conductive substrates for liquid crystal displays

Liquid crystal display (LCD) conductive substrate is an important part of the LCD, the main role is to provide a conductive path for the electronic components in the display. Conductive substrate is usually made of conductive materials, such as copper, silver, etc., these materials have good conductive properties, to ensure that the current flows smoothly inside the display. At the same time, the conductive substrate also needs to have high mechanical strength and stability to withstand the display in the production and use of various stresses and environmental changes.

Liquid crystal display (LCD) conductive substrate inspection difficulties:

In the production process of liquid crystal display, the inspection of conductive substrate is a crucial link. However, due to the complex structure of the conductive substrate, the size of the tiny, and the extremely high precision requirements, so the inspection process has the following difficulties:

Minor Defect Detection:Defects on conductive substrates are often very small, even just a few micrometers in size. These tiny defects can have a serious impact on the performance of the display and therefore require the use of high precision inspection equipment to find and locate these defects.

High Precision Measurements:The size and shape of the conductive substrate needs to be strictly controlled to ensure the performance and reliability of the display. Therefore, high-precision measuring equipment is required to measure the size and shape of the conductive substrate to ensure that it meets the design requirements.

Non-contact Detection:Since conductive substrates are made of electrically conductive materials, conventional contact inspection methods cannot be used. Non-contact inspection methods not only avoid damage to the conductive substrate, but also improve the accuracy and efficiency of the inspection.

Rapid Testing:During the production of LCDs, the inspection of conductive substrates needs to be done quickly to ensure the smooth operation of the production line. Therefore, efficient inspection equipment and algorithms are needed to shorten the inspection time.

Test results:

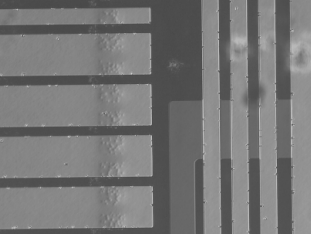

In response to the above difficulties, POMEAS differential interference DIC video microscope provides an effective solution. The microscope utilizes DIC technology in combination with a professionally designed coaxial light source to clearly reveal minute height differences on the surface of conductive substrates, creating an obvious relief effect. This allows defects such as cracks, bumps, particles and holes to be seen at a glance during the inspection process. At the same time, the microscope also has the advantages of high precision, non-contact and fast detection, which can meet the various needs of LCD conductive substrate inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com