Application examples of DIC in LCD conductive substrate inspection

With the continuous development of liquid crystal display technology, the quality and performance requirements for conductive substrates are getting higher and higher. In the production process of LCD, factors such as the surface quality, flatness and conductivity of the conductive substrate have a crucial impact on the overall performance of the display. In order to ensure the quality of the conductive substrate, we used differential interference DIC video microscope for inspection.

Some of the conductive substrates have defects such as tiny cracks and bumps, which not only affect the display effect, but also may pose a potential threat to the life of the display. In order to solve this problem, POMEAS has developed an inspection program - differential interference DIC video microscope to conduct a comprehensive inspection of the conductive substrate.

Detection process:

1, sample preparation: first, a certain number of conductive substrates randomly selected from the production line as the sample to be tested.

2, equipment setup: differential interference DIC video microscope adjusted to the appropriate magnification and intensity of the light source to ensure that the conductive substrate surface can be clearly observed in minute detail.

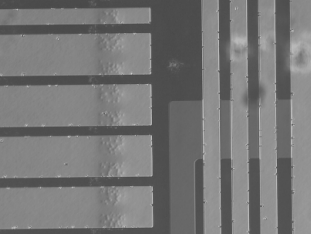

3, detection operation: the sample to be tested is placed on the microscope's carrier stage, by adjusting the focus and position of the microscope, so that the surface of the conductive substrate is completely in the field of view. Then, turn on the DIC function of the microscope to scan and observe the conductive substrate.

4, data analysis: through the image processing software of the microscope, the scanned image is analyzed and processed. The software can automatically identify and mark the cracks, bumps and other defects on the surface of the conductive substrate, and calculate the size and number of defects.

5、Results output: The inspection results will be output in the form of a report, including the location of defects, size, quantity and the corresponding image and other information. This information will be used to guide the adjustment and optimization of the production line.

Test results:

Through differential interference DIC video microscopy inspection, we have successfully found defects such as tiny cracks and bumps on the conductive substrate and accurately measured their sizes and quantities. These defects are difficult to detect under conventional inspection methods, but they have an important impact on the performance of the display. Based on the inspection results, we promptly adjusted and optimized the production line, thus effectively improving the quality of the conductive substrate and the performance of the display.

POMEAS differential Interference DIC Video Microscope has shown excellent performance and precision in LCD conductive substrate inspection. Through the programmed inspection of differential interference DIC video microscope, we are able to detect the tiny defects on the conductive substrate in time and take appropriate measures to repair and improve them. This not only improves the quality and performance of LCDs, but also reduces production and maintenance costs, bringing significant economic benefits to manufacturers.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com