Measuring screw dimensions is not a simple task, and the difficulties are mainly in the following areas:

Thread complexity:Screws have a complex thread structure that includes a number of parameters such as pitch, tooth type, etc., and require high-precision measuring equipment to ensure accuracy.

Limitations of measurement tools:Traditional measuring tools such as micrometers and calipers are susceptible to wear and error during the measurement process due to the nature of contact measurement.

Impact of manual handling:In traditional measurement schemes, the accuracy of the measurement results is largely dependent on the operator's skill and experience, and therefore there is a large amount of subjective error.

The traditional screw size measurement scheme mainly relies on micrometers, calipers and other measuring tools, which are operated by professional quality personnel. This program has the following 3 problems:

1、Low measurement efficiency: Due to the need for manual operation, only one product can be measured at a time, which cannot meet the needs of mass production.

2、Measurement accuracy is limited: the accuracy of traditional measurement tools is limited and easily affected by the operator's skills, so it is difficult to ensure the accuracy of the measurement results.

3, can not record data in real time: the traditional measurement program can not record the measurement data in real time, which is not conducive to subsequent data analysis and quality traceability.

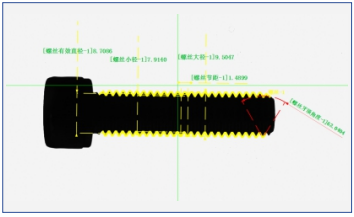

By adopting advanced image processing technology and high-precision measurement algorithms, POMEAS Image Measuring Instrument is able to quickly and accurately measure various dimensional parameters of screws. Its advantages are mainly reflected in the following aspects:

High Precision Measurement:POMEAS Image Measuring Instrument adopts non-contact measurement method, avoiding the wear and error caused by contact. At the same time, its high-precision measurement algorithm ensures the accuracy of the measurement results.

High Efficiency Measurement:POMEAS Image Measuring Instruments are equipped with highly efficient image processing capabilities and automated measurement functions, enabling the measurement of a large number of screws in a short period of time. This greatly improves productivity and reduces labor costs.

Intelligent Operation:The POMEAS image measuring instrument has an intuitive and easy-to-understand interface. Even non-professionals can quickly get started and make accurate measurements. In addition, its intelligent operating functions enable automatic recording of measurement data and data analysis and processing.

Adaptable:POMEAS Image Measuring Instruments can be adapted to the needs of all types and sizes of screw measurement. Whether it is a standard screw or a non-standard screw, the POMEAS Image Gauge is able to measure accurately as long as the appropriate parameters and settings are adjusted.

Real-time Data Logging:POMEAS image measuring instrument is able to record measurement data in real time and perform data analysis and processing. This helps companies to realize digital and intelligent management of the production process and improve overall productivity and competitiveness.

POMEAS Image Measuring Instruments offer significant advantages in screw dimensioning, enabling fast and accurate measurement tasks and improved productivity. With the continuous development and innovation of technology, I believe that POMEAS image measuring instrument will play a more important role in the future, for the screw manufacturing industry to bring more changes and development opportunities.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com