In the industrial field, machine vision inspection technology has been widely used in the next by virtue of its high efficiency, non-contact and real-time characteristics. Especially in solder inspection, the quality of solder is directly related to the performance and stability of electronic products, so it is particularly important to carry out efficient and accurate inspection of solder.

Machine vision inspection program:

Machine vision inspection scheme refers to the inspection scheme that utilizes machine vision technology to acquire image information of the target object through an image acquisition device (such as a CCD or CMOS camera), and digitally processes and analyzes the image through an image processing system, so as to realize the functions of measuring, positioning, and identifying the target object. In solder inspection, the machine vision inspection program mainly includes steps such as data acquisition, data preprocessing, target detection, and evaluation of inspection results.

Solder testing program implementation:

Data Acquisition

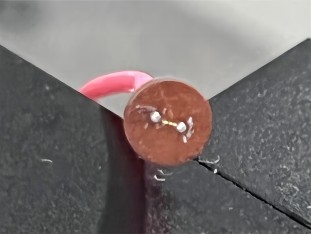

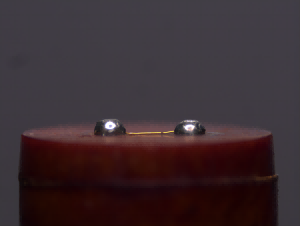

Data acquisition is the first step in solder inspection. With an image acquisition device, we can acquire images or video data of a target object such as a circuit board containing solder. In order to ensure the accuracy of subsequent processing and analysis, the data acquisition process should ensure that the image is clear, the light is uniform, and the angle is consistent.

Data preprocessing

Data preprocessing is a series of processing operations performed on the captured raw image to improve image quality and detection accuracy. This includes operations such as image denoising, enhancement, binarization, etc., which help to remove noise and interference from the image and highlight the features of the soldered area.

Targeted Detection

Target detection is the core aspect of machine vision inspection and a key step in solder inspection. In this stage, we will use the trained machine learning model to identify and localize the target object on the preprocessed image. Through deep learning and other algorithms, we can learn and recognize the shape, size, location and other features of the solder, so as to realize the accurate detection of the solder.

Detecting effects:

Machine vision inspection solutions play an important role in solder inspection. Through the organic combination of data acquisition, data pre-processing and target detection steps, efficient and accurate detection of solder can be realized. This not only improves inspection efficiency, but also ensures product quality and stability.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION