Application examples of machine vision connector inspection solutions

In industrial production, the quality of connectors is critical to the overall performance and safety of a product. Therefore, using machine vision technology to inspect connecting parts has become an effective solution.

Machine vision connectors inspection requirements:

Size inspection: accurately measure the length, width, height and other dimensions of the connectors through the machine vision system to ensure that the dimensions of the connectors meet the design requirements.

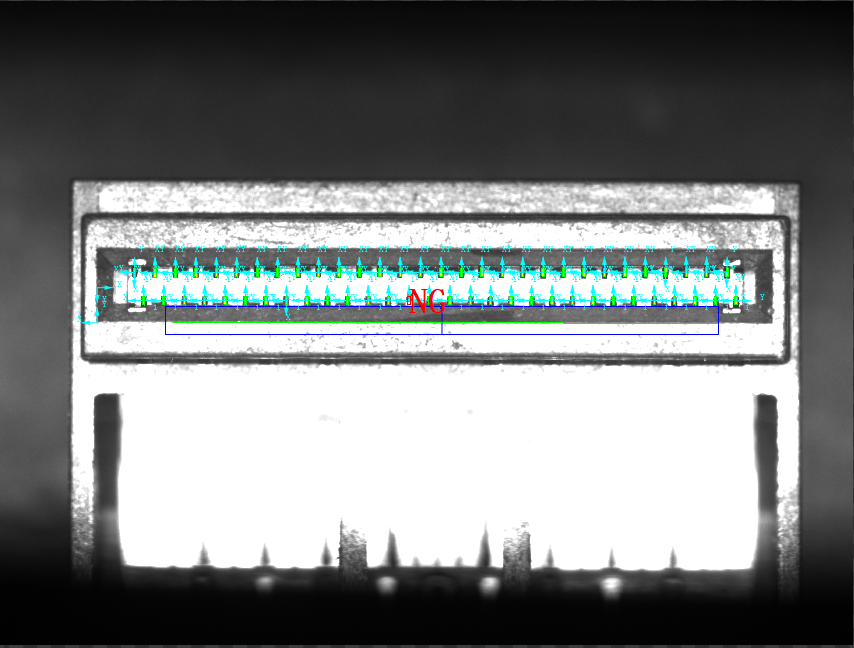

Appearance detection: using image processing technology to detect the surface quality of the connectors, including surface flatness, surface cracks, bubbles, suspensions and other defects identification and judgment.

Position detection: Through feature extraction and matching algorithms, realize accurate detection of the position of the connectors to ensure accurate positioning of the connectors in the assembly process.

Machine vision connecting parts inspection program:

1、Image acquisition equipment: including industrial cameras, lenses, light sources, etc., used to obtain the image information of the connectors.

2、Image processing software: responsible for pre-processing, feature extraction, classification and identification of the acquired image, and output the detection results.

3, control system: according to the output results of the image processing software, control robot or other actuators to carry out the corresponding operations, such as rejecting defective products, adjusting the assembly position.

By inspecting various aspects of connectors such as size, appearance and position, POMEAS vision inspection solutions can accurately measure and identify the connectors to ensure that the quality of the connectors meets the production requirements. It effectively improves the inspection efficiency and accuracy, and reduces the false and missed inspection rate. At the same time, due to the realization of automated inspection, it reduces labor costs and improves the productivity and competitiveness of enterprises.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION