What are the advantages of image dimensioning in tin ball measurement?

The advantages of image size measuring instrument in tin ball measurement, especially when dealing with less than 1mm diameter tin balls and realizing batch measurement, are particularly outstanding, and these advantages are mainly reflected in the following aspects:

Highly accurate measurements:

The Image Dimension Gauge is capable of accurately capturing and measuring the dimensions of tin balls close to 1mm in diameter by means of a high-resolution image sensor and advanced image processing algorithms. The high-precision measurement ensures the accuracy and consistency of tin ball dimensions and meets the requirements of high-precision manufacturing.

Non-contact measurement:

The non-contact measurement method avoids errors or damage to the solder balls that may occur due to contact during the measurement process, and is particularly suitable for tiny and fragile solder balls. At the same time, non-contact measurement also reduces human intervention in the measurement process and improves the objectivity and reliability of the measurement.

Fast batch measurement:

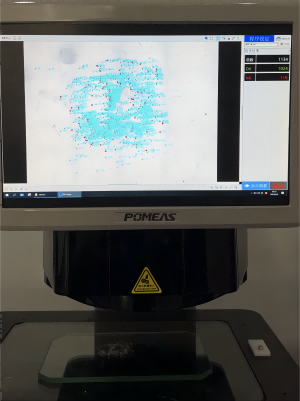

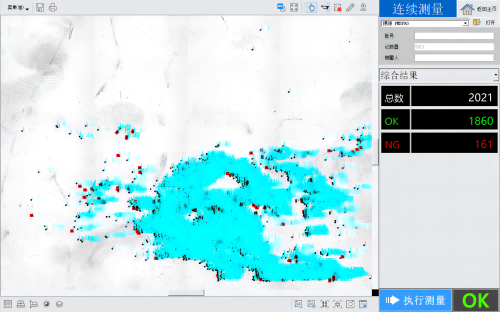

The Image Size Gauge has a highly efficient batch measurement capability that can measure more than 1,000 solder balls at a time and the entire measurement process takes only 3 seconds. This efficient batch measurement capability greatly reduces measurement time and improves production efficiency, making the production and inspection process of tin balls faster and more efficient.

Automation and Intelligence:

The automation and intelligent features of the Image Size Gauge make the measurement process easier and more convenient. Users only need to place the measured tin balls on the measuring platform, and the instrument can automatically complete the process of measurement, data recording and analysis. Intelligent functions can also automatically determine whether the tin ball size is qualified or not according to the preset threshold, and generate corresponding reports and statistics.

Data processing and traceability:

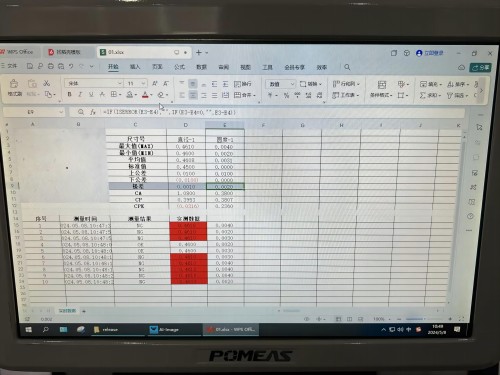

Image Size Measuring Instrument has a powerful data processing capability, which can automatically record, analyze and statistic operations on a large amount of measurement data. The real-time display of measurement results and data analysis results can help operators understand the size of the tin ball in a timely manner, and make appropriate adjustments. Measurement data can be transmitted and shared through the network, which is convenient for users to trace and manage the quality of tin balls.

Adaptable:

The Image Dimension Measuring Instrument can be adapted to the measurement of tin balls of different sizes, shapes and surfaces with high versatility and flexibility. By adjusting the measurement parameters and software settings, it can be easily adapted to different measurement needs.

Repeatability is good:

Due to the automated and highly controllable measurement process of the Image Dimensioner, the results are highly repeatable. This is particularly important for production processes that require continuous monitoring of the dimensional variation of solder balls to ensure consistent and stable product quality.

POMEAS Image Dimension Measuring Instrument not only has the advantages of high accuracy, non-contact, automation and intelligence in tin ball measurement, but also its ability of rapid batch measurement significantly improves the productivity and measurement efficiency, making the production and inspection process of tin ball more efficient, accurate and reliable.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com