Application of Image Dimension Measuring Instrument in Tin Ball Measurement

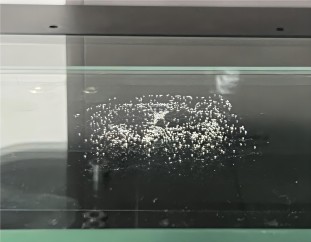

Tin ball measurement as an important part of microelectronics manufacturing, precision instruments and other fields, for the measurement of precision requirements are extremely high, POMEAS image size measuring instrument as a high-precision, high-efficiency measurement equipment, can be for the tin ball measurement provides a more convenient and accurate solution.

Image Size Measuring Instrument Principle

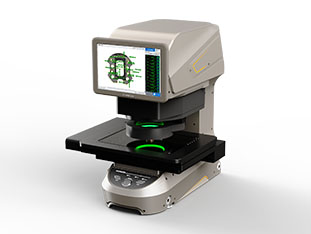

Image Size Measuring Instrument captures the image of the measured object through the high-resolution CCD or CMOS image sensor, and analyzes the image through the image processing software to get the size information of the measured object. Its core components include light source, image sensor, image processing software and other parts. During the measurement process, the image size measuring instrument can automatically adjust the light source brightness, contrast and other parameters to ensure the clarity and accuracy of the image.

Application of Image Dimension Measuring Instrument in Tin Ball Measurement

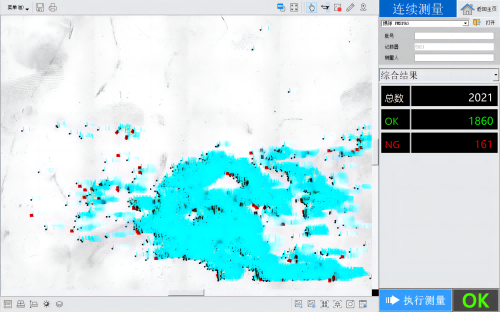

Highly accurate measurements: As an important component in microelectronics manufacturing, the dimensional accuracy of solder balls has a critical impact on product performance. The Image Dimension Measuring Instrument has high-precision measurement capability, which can meet the high-precision requirements of tin ball measurement. Through the image processing software, it can realize the accurate measurement of tin ball diameter, height and other parameters.

Automated measurements: Traditional tin ball measurement methods often require manual operation, which is inefficient and prone to introducing human error. The Image Size Measuring Instrument is equipped with an automated measurement function, whereby the measured solder ball is placed on the measurement platform and the measurement process is completed automatically by pressing a button. This not only improves measurement efficiency, but also reduces the impact of human error.

Data processing and traceability:The Image Dimension Measuring Instrument is equipped with powerful data processing functions, which can automatically record, analyze and statistic the measurement data. Meanwhile, the measurement data can be transmitted and shared through the network, which is convenient for users to trace and manage the measurement results. This is of great significance for the quality control of tin balls.

The application of Image Dimension Measuring Instrument in tin ball measurement shows its advantages of high precision, high efficiency and automation. With the advancement of technology and the expansion of application fields, image dimensioning instruments will play an important role in more fields. In the future, the measurement accuracy, speed and automation degree of POMEAS image size measuring instrument will be further improved. This will bring more convenience and opportunities to the tin ball measurement and the whole microelectronics manufacturing field.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com